[Newsletters]

[Cozy MKIV Information]

COZY NEWSLETTER #61

April, 1998

Table Of Contents |

|

Newsletter Info.

Subscription Info.

Authorized Suppliers

WHAT WE HAVE BEEN DOING

We sent out the last newsletter just before leaving to visit our children and grandchildren in Minnesota over the Christmas Holidays. When we returned home, a package was awaiting us. It was a Christmas present from Steve Wright (he makes the electric nose lift). It was a very accurate 1/12th scale model of out Cozy Mark IV, N14CZ, mounted on a pedestal. What a nice gift! Thank you Steve!

After a few days home to catch up on the mail and telephone messages, we left to spend two weeks on the beach on a Carribean island. For 14 days we had no telephone, television, newspaper, or computer. We didn't have any contact with lawyers and we didn't even know about all the trouble Clinton had gotten into. It was refreshing. We are sorry if we inconvenienced any of you.

EXHAUST SYSTEMS - IMPORTANT

Carl Denk has experienced cracking of the exhaust pipe on the right side from #4 cylinder where the heat muff is welded on. It cracked once, he repaired it, and it cracked again. He has about 500 hours on the pipes. He diagnosed the cause as the differential expansion and contraction of the exhaust pipe compared to the heat muff, which doesn't get as hot, and this differential exerts a tremendous force which will eventually crack the weld or the pipe. If the pipe cracks, there are 2 potential dangers: 1) A crack in the exhaust pipe could allow carbon monoxide to escape into the heat muff, and 2) If the crack is allowed to propogate, a piece of pipe could come loose and go through the prop, and exhaust gas could exhaust into the cowling.

We have discussed the problem with Clinton Anderson, at Custom Aircraft Parts (they make the pipes), and they have changed the design. The heat muff will no longer be welded to the pipe. Instead it will be clamped, which will allow some relative movement between the pipe and the heat muff.

We have almost as many hours on our pipes as Carl had, haven't noticed any cracking yet, but decided not to take a chance with the fly-in circuit almost ready to start. So we ordered a new #4 pipe with muff, rather than sending ours backed to be reworked.

All builders with welded-on muffs should inspect this pipe frequently and rework or replace it at their first opportunity. Custom will rework the pipe and muff for you if you can accept the down time. Otherwise, you can buy a new pipe and muff like we are doing.

We are sorry to put you to this trouble and expense, but it is better to be careful. Thank you, Carl, for calling this to our attention.

VANCE'S COLUMN

Last summer I was in the New York area and stopped by to see a fellow Long EZ builder and flyer. This was his second EZ and consequently had a lot of mods in it. One of them I had been thinking about installing in my COZY for the last couple of years. The other half of this mod I did several years ago and Nat has put it in the 4-place COZY. I’m talking about real cables that hook from the throttle quadrant to the carburetor.

This modification will get rid of the return springs required for a safety back up if you use the standard Brock supplied set-up. The new cables are much better built and engineered and will last almost indefinitely. You can tie these cables in a knot and because they are Teflon lined, will still work easily and smoothly. They are designed for aircraft use and are used in production aircraft.

I'm talking about Cablecraft Cables. You can order them direct from the Tuthill Corp., Cablecraft Division, Phone (206) 475-1080 in South Carolina. They charge by the foot. You can get just the cable or the cable with a vernier type end (like in the Bonanzas and Mooneys) I have both.

My throttle cable has been in for about 7 years and it is 9 feet long.

It runs from just behind the Brock throttle quadrant to the fuel injector servo on my

plane. The Ellison Throttle Body requires a cable such as this in order for it to work.

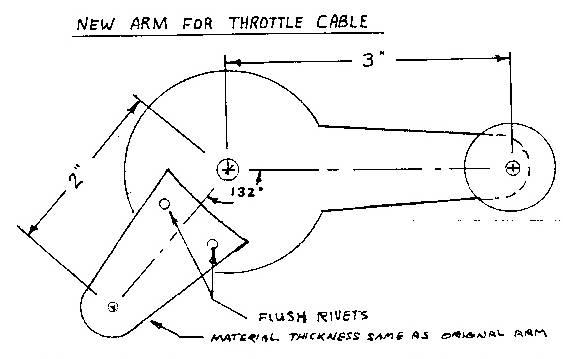

The Brock throttle quadrant also requires a small modification to make this cable work.

Its call a "small arm addition" and I've included a drawing. This only takes an

hour to make and assemble.

The vernier mixture unit requires no modification to work, just substitute it for the Brock unit. The biggest problem is where to place the vernier knob itself. I drilled a hole in the instrument panel 5 inches straight up from the original Brock throttle quadrant. This places the vernier control just above the top of the throttle arc with plenty of finger room for both. This location is not quite into the main instrument panel, but about one-inch below it. After the hole is drilled and the vernier captured, the actual cable runs forward in a looping 180 degree arc of about 20 inches and winds up on the floor heading back into the heat tunnel. It is there that I drilled a 60 degree angle hole into the tunnel and stuffed the cable into it. From there, route the cable per the original plans. When the cable comes out from behind the instrument panel you have a choice of which side of the nose gear cover to lay it alongside. I chose the passenger side as you cannot see it from the normal entry side and it is hidden by the nose wheel cover. My vernier cable is 15 ft long and cost $121 including shipping and handling and takes 3 weeks to get, since it is custom made.

If you are currently building, this mod will take no more time than original equipment, but will offer many more times the reliability and safety of the original Rutan equipment. You will also love the smoothness and quick response to the slightest movement of the throttle and mixture with NO lag or hesitation. This setup is much superior to the old Brock cables. Nothing is free however. These cables are about 4 times heavier and 2-1/2 times the diameter as the original bicycle cables. You will also have to buy the cables in addition to the Brock units. I have fuel injection and have no use for the old mixture and carb heat quadrant, therefore use only the single Brock unit. You can buy these singly and save some bucks.

There are several dozen Velocitys, Longs and at least 2 COZYs flying with this setup. All are happy with the change. The larger Velocitys all require this setup with the larger engines.

If you have any technical questions you can phone me at 817-354-8064 or e-mail me at vaatk@flash.net. Have fun flying!

PUBLICITY

Mark Beduhn published a very nice picture of his Cozy Mark IV in March '98 Sport Aviation. He writes,

"This is my Cozy Mark IV flying over the Arkansas River near Morilton, AR. I had dreamed of building my own plane for years, and finally did it! After 2 years and 2,400 hours of work, N494CZ made its maiden flight on October 15,1997. It has a Lycoming 180 hp IO-360, and a 3-blade Performance propeller. Thanks to a good design and excellent detailed step-by-step instructions, it required very few modifications and adjustments during the 40 hour fly-off period. I can't begin to describe the feeling of accomplishment I feel when flying over the countryside at 200+ mph in a plane that I built myself! Special thanks to my wife Regina who's support, encouragement and tolerance made this project possible. I would also like to thank the mechanics at Conway's FBO, Bill Paul and Brian Smith, for their support in answering my endless questions during construction"

Mark Beduhn,

Greenbrier, AR.

Doug and Patti Pitzer had a very nice article on their Cozy project published in Private Pilot, January 1998.

We will provide both Mark and the Pitzers with a free renewal to the newsletter.

We haven't noticed any other Cozy completions in Sport Aviation or Kitplanes recently. If we have missed anyone, please let us know. In the meantime, we encourage you to send in your pictures and receive recognition for a job well done. For Sport Aviation, address your entries to:

AWARDS

At Vance's suggestion (he sure thinks up a lot of ideas), we had some very nice plaques made by Cozy builder/artist Lon Cooper to honor those builders who have passed the milestones of 500 hrs. and 1000 hrs. on their Cozys. These are really attractive, and truly a work of art, suitable for mounting on the headrest of your airplane, or in your trophy case, or on the wall of your office. 500 hrs. gets you silver, and 1000 hrs. gold. We would like to award these at Cozy dinners at one of the fly-ins. Let us know ahead of time if you qualify.

FIRST FLIGHTS

The following message was recorded on our answering machine March 8, 1998. "Hello Nat, This is Tony Rothwell, calling from Australia. My Cozy Mark IV, VHCOZ flew on March 7, 1998. It flew very nicely! Will write to you with more later. Thank you for a marvelous airplane!"

We know that Jim Wickstrom, Larry Aberg, and several other Cozys are almost ready to fly. But very often we don't hear about first flights until the builder is well into his 40 hour fly-off period. Please let us know so we can share your success with other builders.

STORM DAMAGE

Cozy Mark IV builder David Higgins, who lives in Pembroke Pines, FL, built his Mark IV in 22 months, and has been flying now for several years, had his Mark IV damaged in a tornado a month or so ago. He had dissassembled his airplane in preparation to repainting it. He was working in his large hangar along with a number of other builders, when they became aware of a gathering storm. They decided to retreat to their homes, and about 1/2 hour later a tornado struck the airport. David said the tornado blew out both hangar doors, and one of his wings was picked up and blown end over end about 500 yards. Other debris fell on his fuselage. He said he had to build a new wing and make repairs to the fuselage, but he hoped to be flying again by Sun 'n Fun. He said he considered himself to be very lucky he hadn't stayed in the hangar.

When you hear something like this, it makes your heart very heavy, and you just have to admire someone who can accept it so cheerfully.

SUN 'N FUN

Sun 'n Fun is from April 19th to the 25th this year. We plan to be there, the Lord willing, and if El Nino doesn't get in our way. We reserved our regular exhibition spot across from the FAA building again this year, and reserved our place to stay down at Mulberry. We invited Chris Scida to park his airplane behind ours in our exhibition spot. We haven't seen it yet, but Vance says it is very nice. We invited Steve Wright to display his electric nose lift with us again. He provided a tent for us last year, and we hope he does again this year. We invited Alex Strong to exhibit his electric pitch trim, and Wayne Lanza any of his goodies, like his switch panel and landing brake actuator.

We invited the Cozy Builders Discussion Group (on the internet) to meet at our airplane at 1:00 PM Sunday April 25th. We haven't reserved a forum this year, but would be willing to reserve 1:00 PM each day at our airplane for group meetings to discuss topics and answer questions.

Bill Walsh has reserved the entire side room at the Red Barn Steak House for a Cozy Banquet Sunday, April 25th and would like to pack the room so he doesn't have to let strangers in. If any of you have passed the 500 hour or 1000 hour marks on your Cozys, please let us know ahead of time so we can bring awards along and present them at the dinner. Bill will be making up some new T-shirts (if I send him some new pictures) so bring along some extra spending money. By the way, Lakeland is the strawberry capitol of the world, and we always buy a flat of strawberries on the way to the banquet to share with friends. Those needing rides can meet those offering rides at our airplane between 4:00 and 4:30 PM Sunday. It is important to leave before the end of the airshow, otherwise you will be stuck in traffic. Bill Walsh will supply maps - last year there were a few who received bum directions and never got there.

ARLINGTON '98

We hope to attend again this year, but will keep a sharp eye on the weather. It was bad enough last year.

OSHKOSH '98

We are planning to exhibit there again this year in the same exhibit spot as last year, that is at the South end of the North exhibition building. We have signed up for a forum on the first Friday afternoon, and expect that there will also be a Cozy banquet, same as last year.

EPOXY RESINS

Wicks has been out of stock for some time on the slow catalyst for the original RAE epoxy system, because one of the ingredients was no longer available. It has now been reformulated, and should be in stock at Wicks by the end of March. The resin is 4425A, the fast hardner is 9376B and the slow hardner is 9377B. This epoxy system uses a 100:25 ratio by volume.

In the meantime, there has been a very interesting development. A German company, Martin G. Scheufler, has been making a series of epoxy resin systems for use in the manufacture of sailplanes and airplanes in Europe for many years. They vary in properties, the most important being cure temperature and heat resistance, which is related to cure temperature. Some are room temperature cured, and others required oven curing. Two of them, L 335 and L 285, cure at room temperatures and are ideally suited for the wet layups we make, and have been approved by the German government for aircraft use. Uli Wolter has been using the L285 and recommending it to builders for many years. We have tested both the L335 and the L285. There is something very unique about these resin systems. They have both fast and slow catalysts which can be mixed together in any proportion to give you whatever pot life you want. In the case of L335, the fast catalyst gives a 20 minute pot life, and the slow gives a 6 hour pot life. I tried them both. The properties, after cure, are essentially the same. The catalysts are blue, but after mixing and wetting out, the layup is almost clear. The ratio by weight is 100:38 for L335 and 100:40 for L285, or 100:45 and 100:50 respectively by volume. The ratio of L335 is the same as for Safe t Poxy (in case you have a metering pump set up for Safe t Poxy). The resins are quite fluid and wet out very fast, but will not run in a vertical layup (the word for that is thixotropic). The resin is odorless, not affected by humidity, and has excellent peel strength (unlike 2427). The systems are said to be non-alergenic (low toxicity). The price, on a per gallon basis, will be competitive with the RAE system. The L 285 is slightly more expensive and has a higher glass transition temperature; otherwise, the properties are quite similar. Wicks and Aircraft Spruce will stock L235 for sure, and maybe also L285.

POST CURING OF EPOXY LAYUPS

All epoxy systems have a minimum and a maximum curing temperature. At the minimum curing temperature, for example, room temperature, an epoxy system achieves a good degree of curing, that is, over 80%, and produces a hard, shiny, tack free surface, with good properties, but the properties, including glass transition temperature, are not maximized. For both L335 and L285, the properties achieved from room temperature cures are quite acceptable for aircraft use. The glass transition temperature of L335 after a room temperature cure, would be about 130 deg. F (the glass transition temperature is the temperature at which the epoxy begins to soften and become rubbery). To obtain 100% of the available properties and maximum glass transition temperature requires either post curing or curing at the maximum curing temperature. For L335, the maximum curing temperature or post curing temperature would be about 160 deg. F and results in a glass transition temperature of about 185 deg. F. But to achieve maximum cure and glass transition temperature, the layup would have to be held at the maximum curing temperature for about 16 hours. For L285 the maximum curing or post curing temperature would be about 170 deg. F and result in a maximum glass transition temperature of about 240 deg. F. Again, it would have to be held at the high temperature for about 16 hours.

So is it necessary to post cure your airplane? Actually, no. As either parts of your airplane or the entire airplane sit at temperatures above 70 deg. F, some post curing occurs. Even if your airplane sits outside in the sun, and the ambient temperature reaches 100 deg. F, it will do so gradually, and the post curing will proceed gradually so that glass transition temperature will always be considerably higher than ambient. The wings will not sag. Remember, you are going to paint your airplane white, and the surface temperature (only the top surface in the sun) will only get about 10 degrees higher than ambient. So on a 100 degree day, some post curing will already have occurred, so the glass transition temperature will already be higher than 130 deg. F and approaching the maximum of 185 deg. Now there is a possible exception to this rule. If you are going to paint your airplane black, or some other dark color, a fully post-cured L335 might not have a high enough glass transition temperature (185 deg. F might not be high enough). So, if you intend to paint your airplane black or some other dark color, you probably better use an epoxy like L285, and do some post curing before you park it out in the sun on a hot summer day. Remember, with an epoxy like L335, the glass transition temperature will always be higher than ambient and the epoxy will not soften unless or until the surface temperature reaches the maximum glass transition temperature, which in the case of L335 is about 185 deg. F. If you paint your airplane white, at least on the top, the surface should never reach this temperature even outside in Saudi Arabia in the summer. Even if you are not going to paint your airplane a dark color, but are willing to spend a little extra money on the best epoxy available, consider using L285. That would be our choice. If you do not understand, or have further questions, please contact us.

PILOTAGE

A couple of years ago, Dr. Charles Larson had a fatal accident in his Cozy Mark IV. He hooked the landing gear on a power line which was 37 ft. high, and 1300 ft before the approach end of the runway, with trees on both sides. The NTSB (and all the witnesses, of which there were many) concluded that this was an obvious case of pilot error. He had a reputation for flying low and "dragging in" his approach. The survivors, however, are suing Florida Power. They are claiming that you can't land a Cozy Mark IV on a 4,000 ft. runway unless you are only 37 ft. high 1,300 ft. before the beginning of the runway. This is ridiculous, and gives us reason to review good pilotage in making an approach to a landing. Every student pilot is taught (we hope) that he should always maintain enough altitude on final so that if the engine failed, he could touch down about 1/3rd of the distance down the runway. In other words, he could coast to a point 1/3rd of the way down the runway. In the case of a 4,000 ft. runway, this would be 1,300 ft. after the approach end. Now if you check the Cozy Owners Manual you will see that the clean, power-out glide ratio of the Cozy (both 3 and 4-place) is 23 miles from 8,000 ft. This calculates to a ratio of 15 to 1 or a power off glide angle of 3 deg. 50 min. Now, if Mr. Larson had been following this rule for minimum altitude on final, he would have been 172 ft when passing over the power line. This is the minimum recommended altitude on final! He was at least 137 ft. below the minimum recommended altitude. But, you say, what if you want to touch down on the numbers? Well, that is what the landing brake is for, to steepen your angle of approach. Have you noticed how much you slow down when you lower the nosewheel and deploy the landing brake? You then have to lower the nose and steepen the angle to maintain speed. This helps you to lose the excess altitude you need for safety, and allows you to approach above the minimum altitude on final and still hit the numbers. The worst time for an engine failure is on final, and if you maintain excess altitude, you can always reach the runway. There should never be a reason for an airplane to crash short of the runway, even if the engine stops dead. Even if you come in much too high, like 800 ft. when you are only 1,300 ft away, you can always deploy both rudders in addition to the landing brake and come down as fast as a Cessna (sort of like a brick)! In our marvelous system of justice, however, contingency fee lawyers hope for a jury that doesn't understand airplanes and someone with deep pockets that they can blame accidents on.

ENGINES

Dick Rutan (who, if you remember, just finished flying around the world with Mike Melvill in their Long Ezs powered by 0-360 Lycoming engines) was visiting a builder who was building a Velocity, and planning to install an automobile engine. Dick said, "You should never install an untested engine in an untested airplane!" The builder said, "The Velocity is a tested and proven design." Dick said, "That may be, but the airplane you are building isn’t tested and proven yet!" These are words to live by, with the emphasis on the word LIVE.

We have been criticized for urging builders not to make changes, but to stick with what has been proven. Some say we are just trying to protect our butts! Get real! It is your butt and those of your loved ones we are trying to protect. Please see the letter from Clark Lydick, of Performance Props.

Aviation can be very safe, but it isn't very forgiving of errors. "There are bold pilots and there are old pilots, but there aren't very many old, bold pilots".

PITOT TUBE AND LANDING LIGHT

There has been some discussion on the internet about alternate locations for the pitot tube and landing lights.

We located the pitot tube in the nose, the same as on the Long EZ, because that is the one place we know the air is undisturbed. Instead of just using a piece of 1/4 in. aluminum tubing, like in the Long EZ, which kept jabbing us as we were working around the fuselage in the shop, or people would step on when we parked nose down at airshows, or mud dobbers would crawl in, we made ours removable. We burried a 1/8 in. pipe fitting in the nose, and shortened a AN 840 hose nipple, which screws into this fitting. On the ground, we can replace the hose nipple with an adapted eye-bolt, for a nose tie down. Builder Jack Wilhelmson even invented a home built heater for the pitot in this position for those who want to fly heavy IFR. We don't like a location under the fuselage, or under the canard, or on the top of the winglet for a number of reasons.

We have stayed with the landing light location, retractable and under the fuselage, same as on the Long EZ. It has two positions, one for landing and the other for taxiing. We never use ours for landing because we think runway lights give us better visibility and depth perception for landing (that's what we were taught in the Navy). Some builders install a light in the nose, but it has to be fixed. We recommend against installing lights in the strakes or wings because you have to cut into structure, and the lights reflect off the canard and destroy night vision.

We try to give you reasons for what we recommend, but if you decide to do otherwise, its up to you.

BUILDER HINTS

- Caution: The CZNC-12A elevator torque tube offsets were designed to eliminate the slot

that would otherwise have to be cut in the side of the fuselage to let the torque tube

wobble as the elevators are moved up and down. This slot caused a draft around the feet.

With the offset, only a round hole is needed in the side of the fuselage, and the draft is

eliminated.

The CZNC-12A is a precise part with a lot of machining and welding. As a consequence, it is also expensive. If you notice, there is a slot milled into the I.D. to allow the hinge pin to pass through without interference. Where this slot is milled into the wall, the wall is only about 0.010 inch thick. If you improperly clamp this part in a vise, or apply too much pressure on it in a drill press (like with a dull drill), it is possible to collapse the thin wall section, which destroys the part and requires that it be replaced or reworked. You cannot expect Brock Mfg. to replace or rework this part free if you damage it by carelessness. It is suggested that you exercise caution when drilling through this part to attach it to the elevator torque tube. It is suggested that you purchase new drills, and start out with a 1/16 in. and then a 1/8 in. pilot hole, so that you minimize the pressure when you open it up to 3/16 in. Brock has replaced a couple of these parts as a courtesey, but has advised us that they cannot continue to do this, because they are very expensive to rework or replace. Brock has asked us to ask our builders to be careful.

- The bearings which we recommended in the last newsletter, FMN-10 are also in stock at Aircraft Spruce. The nosewheels we recommended are also in stock at Aircraft Spruce as A1230. The new German Epoxy L335 and L285 will also be in stock at both Wicks and Aircraft Spruce. Sorry I didn't make that clear, Jim.

- The foam cutting templates for the canard airfoil for either the Cozy III or Cozy Mark IV are the same as used on the Long EZ. In the Long EZ, the level lines for cutting the airfoils may or may not have coincided with the longerons, after mounting the canard in the fuselage. However, In both the Cozy III and Cozy Mark IV, the level lines on the foam cutting templates do not coincide with the longerons! We repeat. The level lines on the canard templates do not coincide with the longerons! That is the reason we instruct the builders to use the elevator deflection template to level the canard while installing it in the fuselage. The canards in the Cozy III and Cozy IV are purposely installed at a greater angle of incidence (as compared to the Long EZ) because the fuselages in the III and IV are wider, contribute more lift than on the Long EZ, and that lift is destabilizing. That is, the higher the nose, the more lift is generated by the fuselage. The canard, therefore, must be set at a higher angle of incidence than in the Long EZ, so it stalls sooner, to offset lift contributed by the fuselage. It is very important to install the canard at the correct angle of incidence. If the angle is too low (as we suspect in Pat Young's accident), the airplane could be susceptible to a main wing stall.

FOR SALE

- There has been a change in suppliers for the nose gear crank ratchet, previously supplied by Dr. Curtis Smith. The new supplier is Bill Theeringer. His prices will be: 44807 Ratchet (plain)$49.95

- One Cablecraft throttle cable for Ellison carburetor, as per plans for the Cozy Mark IV. New. Never used. $75 including shipping. Call (602) 671-7355.

- Rebuilt aircraft instruments, much less expensive than new, guaranteed. Contact: Howard Francis, 5613 S. Crows Nest Rd., Tempe, AZ 85283 (602) 820-0405.

- Cozy builder, Bill Walsh, makes tee shirts and sweatshirts in various colors and adult sizes. They have a picture of the Cozy Mark IV on the front and back He may have other items, such as jackets, caps, and pins. Contact him at PO Box 160884, Altamonte Springs FL (407) 695-3543.

- Cozy builder Wayne Lanza supplies an electric speed brake actuator kit with all the parts needed for installation, with instructions for $275. He now has a switching and breaker panel for the Mark IV. It is similar, but not identical to the one we had made for our plans model. He is using the highest quality DC switches and circuit breakers, and pre-wires the panels, making the rest of the electrical system installation very EZ. Cost is $425. We heartily recommend his products. Contact him at: 9425 Honeysuckle Dr., Sebastian, FL 32976 (561) 664-9239.

- Custom Aircraft Parts (see "Authorized Suppliers) manufactures our 4-pipe stainless exhaust system which we believe is superior to anything else available or advertised for the 3 and 4 place Cozy. Cost is $500, which includes shipping and handling.

- Vance Atkinson supplies fuel sight gauges. They are a clear bubble with a white background. $35 per set. Contact him at 3604 Willomet Ct., Bedford, TX 76021-2431 (817) 354-8064.

- Steve Wright is making electric nose-lifts for the Cozy 3 and 4 aircraft. It will raise the nose with full fuel and baggage and at least one person sitting in the front seat. We have installed one and like it. Contact him on (616) 373-8764 for pricing.

- Alex Strong is making a neat electric pitch trim system. Cost is $175. We have installed one and like it. Contact him at (619) 254-3692.

- Bill Bainbridge at B & C makes lightweight starters, alternators, linear regulators, current limited chargers, and the best dry batteries we have ever used. His most recent product is a 90 degree spin on oil filter which mounts on the Lycoming accessory case without requiring any oil hoses. We are using all of his products and really like them. Contact him at (316) 283-8662).

- Featherlite (see "Authorized Suppliers") makes many pre-fab parts for the Cozy 3 and 4, including pre-cut wing and canard cores. We have used all of their parts and can vouch for the quality. They have also taken over the manufacture of propellors from Bruce Tifft's estate. These were good propellors, with a urethane leading edge, and we are pleased to see that they are available again.

44812 Ratchet (Chrome finish) 59.95

Shipping and handling 5.00

Extra for Visa & Master 3.00

Contact him at: PO Box 21645, Santa Barbara, CA 93121 Home: (805) 964-5454; Shop (805)964-5453; Fax (805) 683-8577.

LETTERS FROM BUILDERS

3/4/98

Dear Nat,

I have the same 3-blade Performance prop that you list in the newsletter, but with an 8 inch prop extension. Maybe that is part of the reason my plane is so quiet. I took sound measurements again yesterday and got 92 db (full throttle at 5,000 ft.) Based on what I have been reading lately, my plane is several db quieter than normal. When I take other pilots for rides, the first thing they notice is the fantastic visibility, the second thing they notice is how smooth and quiet it is. Of course the Cessna pilots are totally green when they look at the airspeed indicator!

Thanks for the great design! I hope to see you and Shirley at Oshkosh and then Copper State. I wanted to go to Lakeland, but it looks like I won't be able to get off work.

Mark Beduhn

Cozy IV N494CZ

12/2/97

Dear Nat & Shirley,

I am sorry for not writing sooner, but I am enjoying flying my Cozy Mark IV so much I don't want anything to interfere! I am happy to report that on 4/3/97, my Cozy Mark IV, N55CR made its first flight. When I got out onto the runway to do my high speed taxi test, everything felt so good, that I took off and made my first flight. The flight lasted for forty five minutes and I went up to an altitude of 6,000 feet above the airport. The landing was very smooth, and the plane handled exactly as advertised. My aircraft has a 0 timed 0-360 Lycoming and a 3 blade Performance prop, all electric trim and landing brake and gear. I brought a cowhide home from Sun ‘n 'n and hand sewed the taupe leather interior. The instrument panel has carbon fiber overlays and full instrumentation including a stereo system. To date, we have 150 hours on the plane (with no problems so far) and have taken trips to Rough River Kentucky, Georgia, Maryland and Florida. My top speed thus far has been a very fast 216 mph at 8,000 feet. We are extremely pleased with both the plans and the finished product. If anyone comes to this area and would like to take a flight, I would be happy to show off the plane. Thank you again Nat, for such an excellent aircraft.

Chris Scida

Rocky Point, NY

12/16/97

Dear Nat,

Thank you Nat for the Cozy Newsletters. It is always interesting to see builders comments and letters and to compare their thoughts with the feedback that I get directly from Cozy builders buying my propellors. If I did not have this independent survey of opinions, I would be inclined to feel that you feed back to your readers only the letters that support your design. The interesting fact is that the feedback directly to me is that they are extremely pleased with the performance of the Cozy and consistent with your newsletter. I have found out over many years of supplying propellors to many homebuilt designs that my Cozy customers are consistently pleased that their planes exceed their expectations. HUM, I wonder if this is because you are a bit conservative and not hyping your product?? I have not been able to come up with a different answer. Yesterday, I had a call from Mike Pollick, a Velocity builder who uses my props and he is real excited to be building a Cozy Mark IV. It is always great to convey my knowledge of very pleased Cozy builders.

I have been known in the past to tell customers that I thought you are a little too protective of only making Cozys your way, based on only your proven parts and building techniques. Well, I lost a previous customer (Mark Ewart) and his family during the Thanksgiving holiday because of what now appears to be an in-flight adjustable propellor failure. Mark had decided to give it a try with an in-flight adjustable prop because it gives a shorter take off, which UNLIKE the Cozy Mark IV, is a complaint of many Velocity owners. You considered the same propellor a while back and because it wasn't proven, you took the "old Nat conservative approach" and declined using your customers planes as test beds. Old "stuck in his own ways, Nat" does it again. Protects his customers by his conservative PROVEN ways.

Well Nat, THANK YOU. I have a high regard for your approach.

Sincerely,

Clark Lydick

Performance Props

12/13/97

Hi Nat,

Thought I'd send you a progress report on my 1 year anniversary of buying the plans. I'll include a picture (of course the front wheels in the picture are not a design change, just an oakie building technique). Its been an exciting year, learning, and progressing as money will allow. I have jumped around a little. I'm currently working on Chap. 19, cutting the wing jigs. I do not have the nose gear yet, so I just passed that for now. I've been sidetracked some with getting my pilots license, but after one year, and over 550 hours of "documented" work, I'm very happy with the progress. I'm thankful for the good plans and the newsletter, which I enjoy reading very much. And also meeting other builders, which has helped me get this far.

Best luck to you in your continued efforts, Nat. Keep up the good fight!

Bob Smith

Bakersfield, CA

12/21/97

Dear Nat,

Cozy N171BH, now with flight test and FAA signoff complete, has 46 hours on it. The interior is being sewn up, and spinner and wheelpants will come next. I plan to attack the fly-in circuit next year as my work schedule allows. I can't wait.

Brian Heinitz

Roseville, CA

12/8/97

Dear Nat & Shirley

We missed our target of finishing by the end of 1997, and now have to work towards a spring of 1998 first flight. She presently sits on her wheels with the wings mounted, the engine is in, and I am mounting the cowls We are both well here and trust all is well with yourselves. Good wishes for Christmas and the New Year.

Bob & Angela Allen

England

1/20/98

Dear Nat,

Happy new year! After reading the flying qualities report on the Velocity, along with the follow up article "Rock & Roll" by Ed Kolano in the January 1998 issue of Sport Aviation, I decided to do some more testing on my Cozy.

In summary, the flying qualities report found that in the landing configuration at 90 KIAS, the Velocity has a strong Dutch roll "interfering with the airplane’s roll rate during aileron-only rolls from 30 degree right wing down to 30 degrees left wing down." With full left aileron applied, the Velocity begins to roll as it should, but a strong adverse yaw causes enough sideslip to roll the airplane against the direction of the aileron input. So a yaw-roll oscillation occurs, fighting the desired roll input and turn, resulting in some pretty sloppy, and annoying flying. Now, any normal pilot would have applied coordinated rudder and the messy wing rock and nose wag would have been avoided, thereby keeping your passengers from getting sick! But I couldn't wait to test for this on my Cozy.

But due to El Nino, I had to wait. In my flight test program, I tested for Dutch roll, adverse yaw, and checked dynamic roll response. My notes show that all Dutch roll attempts dampened within 4 cycles (max allowable is 6). Yaw tested as neither adverse or proverse. Dynamic roll response revealed no roll hesitation, with proper balance between degree of stick input and roll rate. In short, my Cozy passed these and other stability and control tests with flying colors. But did I miss something? The Sport Aviation article got me wondering.

Today the rains finally took a break and unbelievably: no fog! So I launched. I set N171BH up in the landing configuration and tested at speeds between 80 and 100 KIAS. Starting with an established 30 or 45 degree left or right bank, I applied aileron-only full stick inputs rolling out of the bank, through level flight, and through an equal bank in the opposite direction. All that worry for nothing! My Cozy exhibits none of the strong Dutch rolling found in the Velocity article. Adverse yaw was very small to none at all. There wasn't even a hint of Dutch roll. Naturally, roll rate was slower at lower than at higher speeds, and I didn't time it. But each attempt resulted in a smooth and steady and continuous roll from the starting point through wings level to the opposite side. I estimate the total time for each maneuver was between 4 to 6 seconds, depending on starting bank angle and airspeed. Then, once coordinated rudder is added (don't need much) my Cozy handles very well in the pattern.

One thing I haven't tried yet is to seal the gap between the top wing skin and aileron with tape over the hinge line. A friend of mine says it makes the ailerons noticeably more responsive in his Varieze. I plan to try it on my airplane. A faster roll rate at low pattern speeds could be useful if I ever get wrapped in somebody's wake at a busy airport. Meanwhile, I'm very pleased with the flying qualities of the Cozy. Now, if I could just get a set of wheel pants and a spinner installed.

Brian Heinitz

Roseville, CA

Editor: Brian has a 3-place. The better directional stability he refers to at low speeds could be due to the lower winglets, which the Velocity may not have had. Also, roll response is faster on the Mark IV, because the ailerons are farther outboard due to the 2 ft. greater wingspan.

12/4/97

Dear Nat,

Hope you and Shirley had a Merry Christmas and 1998 is good to both of you.

I just finished totaling my 1997 cost and construction time for Cozy #412. After almost 3 full years, I have spent $11,700 and put in 1,741 hours. I installed my center spar and realized I needed my canopy and side windows to continue. I ordered from Airplane Plastics, but with a 4 week delivery, I have come to a temporary stop. Gives me a chance to catch up on some "honey-do" jobs. I normally play with "the plane" two or three hours almost every day before going to work on the evening shift. I'm really proud of what I have accomplished so far.

If another builder in the mid-west wants to same some time, I have a jig for the turtleback. It was built by Kip Davis of Neesho, MO and we have both used it and would like to pass it on. Give me a call at 573-468-4120. I hope to send you a completion photo before my next subscription runs out. See you at Oshkosh!

Gary Juergens

Sullivan, MO

2/2/98

Hi Nat & Shirley,

I hope you both had a pleasant and safe holiday season, and had a safe trip on your vacation. I would like to let you know how much I still enjoy the newsletter. I hope you will continue to include letters from builders who have stayed with their projects for years until they have finished them. Those letters are my support network, for I am going through the same circumstances as many of the writers. But they went on to finish their projects, and every time I read about one of them, it makes me that much more determined to be like them. Thanks for all of the great support over the years. I hope to get out to AZ one day to meet you in person.

Wilbert Leonard

Danville, VA

2/3/98

Dear Nat,2/3/98

Enclosed are a couple of pictures from almost a year ago. I have since installed the spar, firewall and turtle back. I am currently working on the control system awaiting warmer temperatures for my last big layup, the fuel strakes. Thanks for a fun project!

George Mellen

Westerville, OH

2/3/98

Nat,

Chris and I haven't been able to start the construction of our Mark IV, but it’s not far off now. We'll be under way this spring. I'm anxious to smell fresh epoxy ahgain. It's hard to believe but my Varieze (picture enclosed) is starting its 7th season of flying. See you at Sun 'n Fun.

Bernie Nitz

Milan IL

2/8/98

Hi Nat & Shirley,

Family life has kept me busy, but the Cozy moves on. I completed the speed brake and installed Wayne Lanza's electric mechanism. Fun to play with in the garage... Wayne did very nice work on the bracket arm fabrication and the mechanism. Next is gear reinforcement and attachments... Will probably finish in a year or two.

I find the posts on E-mail interesting. The latest regarding the engine development is fun to read. I think it will save a lot of people a lot of time, by not starting a project (engine) they can not complete.

I read your suggestion in Kitplanes regarding the use of the name "Experimental". I agree that name is a lousy choice for planes that have been proven very safe. I see only one area that needs some review for the concept to work. That would be all the little modifications that we seem to like to do. For example, the use of Vance Atkinson's fuel sight gauge is a modification not listed in the plans (but in the newsletter), but is far superior to the plans method. Other "small" changes include the retractable step, retract nose gear, electric trim, etc. Perhaps an official list of acceptable modifications would be required to keep a plane in the "Custom Built" category. Perhaps you could allow modifications to be considered after a plane has successfully flown, then modified, with all changes documented. This worked well for you with the canard span vs c.g. concerns, as well as the need for the lower winglets. While your suggestion was a good one, it has a potential of killing the concept of "Experimental", by putting creative minds in the position of losing their type ("custom") rating if they make any modifications at all. Any proposal to the FAA should include room for safe growth of each design, but with the designer in control. Your friend in South Florida.

Steve Blank DDS

Port St. Lucie, FL

2/4/98

Dear Nat,

Just a note to let you know how COZY 267 CZ is doing. I installed an 0-320 about 8 months ago and after a few months of testing and debugging, I'm seeing about a 300 ft. shorter take off with a climb of 1500 to 1800 fpm. The top speed has increased about 10 kts. This is a much better performance over the 135 hp 0-290

As per our last phone conversation, have you heard if cutting the exhaust pipes off at an angle has any advantages? (Editor: No) Hope to see you at Sun 'n Fun in the spring!

John Ashe

Durham, NC

1/2/98

Dear Nat,

I recently began flying Cozy aircraft 98RH which was built by my father, Ray Hart of Williamsburg, VA. Along with the aircraft he gave me a library of past issues of your newsletter, which I have really enjoyed reading and found very informative. I am amazed at how much there is to learn about these aircraft. I look forward to receiving future copies of the newsletter and flying your design. While I am still learning about the aircraft, so far it is a great flying machine!!

Terry Hart

Lawrenceville GA

3/1/98

Dear Nat,

It was nice to see my name in print in newsletter 60. I hope my contribution helps other builders. One thing I didn't mention is that after using up my last batch of 2427 epoxy, I switched to Safe t poxy II, with which I have been very satisfied. It definitely seems to be more tolerant of the long layup times associated with some stages of the project. When you are doing something complex for the first time, there's nothing like a proven product, and once again I have to endorse the many basic guidelines established years ago by But Rutan and continued by yourself. I do watch the internet for useful information, but it's amazing how many builders seem intent on striking off on their own with unproven ideas, despite all the widely reported problems associated with such activity. I'm going to stay strictly with the plans, get my plane in the air, debug it thoroughly, and ONLY THEN decide whether I really want to change anything. So far I've found the project very gratifying. While being labor-intensive, it is quite straightforward if one takes the time to read the plans thoroughly and think things through.

I've enlisted my daughter's help on the larger layups lately (the outside of the fuselage). We recently enjoyed being able to sit in the fuselage tub for the first time. While waiting for a chance to devote full-day sessions to those layups, I moved ahead in other areas, such as building the headrests, installing interior landing gear reinforcements, etc. Yesterday I completed glassing the headrest/shoulder harness mount and will finish that chapter soon. Next will be wrapping and mounting the landing gear.

Regarding the mounting of the headrests, I've wondered for some time whether keeping the left headrest separate and attached to the canopy might compromise some of the roll-over protection it provides when attached to the seat back as in the oringinal plans. Do you believe that the headrest is the primary roll-over protection, or is the canopy bulkhead and turtleback structure intended to serve that purpose on the Cozy? I have heard of no Cozy accident where roll-over or roll-over protection were factors. (Editor: The only roll-over I have heard of was when the Harrises landed their 3-place in a muddy field. It tipped over, landed upside down, but didn't even break the canopy or turtleback. I think there is more than enough protection).

I'm on the way to Seattle for a business trip to Boeing, and plan to look in on Eric Westland's project while there. He should be in the midst of painting, so I hope to get some useful pointers to apply to my own project. I've hinted to my wife that it might be fun to make a Florida trip in April to Sun 'n Fun. If we can get some reasonably-priced tickets, we might see you there. Hope so, though the recent El Nino activity may affect attendance and make it a wet fly-in.

Paul Kuntz

Lancashire, UK

2/25/98

Nat,

The plans look great. I'm sure you've heard this before, but I'll say it again. Thanks for providing a means to achieve a dream; building and flying my own aircraft.

I look forward to a lot of hard and rewarding work during the coming years.

Alan Wirbisky

Eden Prairie, MN

1/2/98

Dear Nat,

Thanks for the advice about props. Please find enclosed a photo of what may well be unique (two MKIVs side by side under construction in the same shop), however the photos are out of date as by the time you get this, both fuselages should be fitted with nicely curved nose cones and be fully carved and glassed. I am working on a glass panel cockpit display that will provide in-flight real-time display of navigation info overlaid on a standard aviation chart, the system will use gps for its position information and should be able to be linked to the autopilot so that the airplane will fly any pre-programmed route. The system will also be capable of displaying engine performance info if required, but personally I prefer pointers and dials.

Thanks for a great airplane design! When we get flying, just watch out for the interest in your airplane over here.

Keith Skull

Bettws Newydd UK

3/11/98

Hi Nat,

Cozy #219 is getting its gear on. What never ceases to amaze me is the ease with which it all comes together. First you make a bulkhead, then you make another, then you put it all together on the table, later you make the gear, drilling holes all the way, none related to each other, BUT then you pick up the gear, put it in place and but for a 1/16 in. adjustment, it all fits like a glove and is ready to receive the axle installation. What I'm really saying is : Thanks! The plans work great!

Chris van Hoof

So. Africa

12/10/97

Dear Nat,

Here's an update on #565 and a couple of questions. We're continuing to have a good time building this plane. Progress isn't as good as we would have liked but other things (like my regular job!) keep getting in the way. However I've completed the fuselage and the canard, and am part way through the main spar. The canard went OK although I am off by about 1 degree in getting the required 15 degree up-travel so there's some rework left to do. The nose installation is done, including the nose gear, rudder pedals and master brake cylinders.

Now for the questions! I hear from Wicks that 2427 is no longer available, and they don't have the RAE 2426 slow catalyst yet. Is there anything else coming on the market? (Editor: See above write up on the German epoxies.)

Regarding the choice of engine: I have been looking for a Lycoming 0-360 or IO-360. I just happened to notice in the Kitplane listing for the AeroCanard (grrr!) that they recommend a left-hand (LI0) Lycoming for their airplane. Is there a reason why a left-turning engine should be considered? (Editor: Only if they are more readily available and less expensive. As long as you have the appropriate propellor, it won't make any difference.)

Thanks for your continued help, Nat. Merry Christmas and hope to see you at Sun 'n Fun in April.

Todd McLean

Baton Rouge, LA