[Newsletters]

[Cozy MKIV Information]

COZY NEWSLETTER #60

January, 1998

Table Of Contents |

|

Newsletter Info.

Subscription Info.

Authorized Suppliers

VACATION

We plan to be in Minnesota December 19th to the 28th to celebrate Christmas with our extended family, but will try to check for messages and answer calls during that period.

We will be out of the country on vacation from January 11th to the 24th, and will have Shirley Lewis Smith in our home and office to answer as many questions as she is able. We hope this will not inconvenience you.

WHAT WE HAVE BEEN DOING

If you will permit me to reminisce, when I retired from 3M, 12 years ago, I was so thankful that I no longer had to write monthly, quarterly and annual reports on the development work I was doing. Now, as you can see, I am still writing quarterly reports, and we are up to newsletter #60.

I remember as a Freshman in college, all of the engineering students hated to take "Engineering English", but I remember the young female professor admonished us that no matter how good we were as engineers, if we didn't write good reports, management wouldn't appreciate what we were accomplishing, and our careers would suffer.

Now, it's not a matter of career, but rather being effective in helping people build safe airplanes and operating them safely. No matter how good an airplane the Cozy Mark IV is, no matter how good the documentation, no matter how thorough the testing and no matter how good the reputation, I feel that it is still necessary to use all the writing and communication skills I possess to try to persuade builders to stick to what has been tried and proven, and not make dumb design changes or take dumb risks. I consider that the responsibility I have for the safety of my builders is greater than the responsibility I had at 3M over products and manufacturing processes. If I come on a little strong at times, it is because I want you to build the safest possible airplane and fly it the safest possible way! I hope that is what you want as well.

COPPERSTATE

Our own Copperstate fly-in this year (October 9-12) was a huge success. It competes with Arlington, WA for 3rd place after Oshkosh and Sun 'n Fun. The weather was gorgeous! Clear skies, 80 degree temperatures and low humidity. There were airplanes almost as far as the eye could see. Four Cozy's showed up. The Cadwells and Elkinds from California, and Brian Giesler from Sun City. This fly-in involves a 10 mile cross country flight for us. A number of our builders were there, some came quite a distance. We took prospective builders for rides, and got to demonstrate the Cozy Mark IV in repeated 220 mph low passes before the crowds. Our dinner at Anzio's Landing, at Falcon Field was well attended; 36 builders, prospective builders and friends attended, and everyone seemed to have a wonderful time getting acquainted and exchanging experiences. Allan Aaron and his family were there all the way from Australia. Arizona is a wonderful place to visit in October (or any time for that matter) so we encourage more of you to join us next year!

FALCON FIELD AVIATION DAY

Closer to home at our own airport we had an "Aviation Day" on November 1, complete with airshow. It was well attended, and we exhibited our Mark IV there (this involved taxiing it to the flight line and setting up a booth). There was much interest in our airplane, and almost everyone asked, "Is this like the airplane John Denver was flying?" We were amazed at how interested the public was in this matter. In the aftermath of this unfortunate accident, when so much public attention was directed toward "Experimental" airplanes, the EAA did a wonderful job educating the press and the public that "Experimental" airplanes did not mean that these airplanes were untested. "Experimental" airplanes are simply airplanes built by individuals, most designs were very thoroughly tested, were state-of-the-art, and many were better built than factory built airplanes.

JOHN DENVER'S ACCIDENT

It has been reported that John Denver's fatal crash of a Long EZ was due to the fact that it was not built according to the plans and recommendations of the designer (Burt Rutan). A non-approved fuel valve, which has a brass plug in a brass body and is prone to sticking, was mounted on the firewall. It was operated by a long torque tube from the firewall to the front seatback, and had a handle located under the pilots left arm near the shoulder. The handle was not placarded to show valve position. It was reported that when John Denver took possession of this Long EZ, after it had just been repainted, the fuel valve was frozen, and it could only be turned with vise-grips. It was eventually freed somewhat, but still did not turn very freely. It was reported that John did not start out with full tanks, and did some flying before the accident occurred, and it is presumed that the tank in use went dry when he was over the water at 300 to 500 ft. To switch tanks would have required him to loosen or release his safety harness, take his right hand off the stick, lean forward and turn his body to grab the fuel valve handle with vise grips with his right hand. These airplanes are sensitive in pitch, and if you trim them for level flight, and then lean forward, the nose will go down. At such a low altitude, the distraction of running out of fuel, having to loosen the safety harness, take his hand off the stick, lean forward and turn around to wrestle with a sticking fuel valve, certainly could explain what happened. It was reported that the torque tube was broken and the fuel valve was found in a mid-position, i.e. not completely open. NTSB investigator Pettersen said, "This fuel selector question points out how important it is to stick with the plans. I can't stress enough the importance of builders complying with the designers instructions". We have repeatedly advised builders not to change the design of the fuel system, but to build it and locate the selector valve as shown in our plans. As recently as newsletter #59 we cautioned builders about changes to the fuel system. See newsletter #59, page 9, Unapproved Changes 13, 14 and 15. We are conceded that inspite of our repeated warnings, there may still be some builders we have failed to convince, who may still be mounting their fuel valves remotely, and setting themselves up for a similar accident.

We have also discussed in previous newsletters that we normally cruise anywhere from 8,000 ft to 14,000 ft, and program the switching of tanks to occur over or within gliding distance of airports. We think this is a wise precaution, and recommend it.

ILL ADVISED DESIGN CHANGES

Remember, only the designer is qualified to advise on changes to his design. After all, his reputation is on the line.

Some builders think that because we register our airplanes as "Experimental", they are encouraged to make design changes. We have asked the EAA to renew their efforts to have a new category established for home-built airplanes, namely CUSTOM-BUILT. This category would be for home-builts built in exact accordance with a proven design. Those one-of-a-kind or modified home-builts not built according to a proven design would continue to be registered as EXPERIMENTAL. This would clear up a lot of confusion in the market place.

BRAKES

We have been asked for our opinion of Matco three piston brake assemblies in lieu of the Cleveland heavy duty brakes. Of course, we have never used Matco brakes, except on our Varieze, when they used to be Rosenhan. We had one brake disc crack (they were cast iron), which almost caused an accident, and the replacement discs were warped and we had to have them reground at work. We had the master cylinders fail twice, so we couldn't even taxi. Wicks has reported having complaints with Matco wheels and brakes. One of our builders repaired a Cozy for another owner who had purchased a Cozy that had Matco brakes. He said the Matco brakes were poorly made, would drag in landing (really bad news), would overheat, and sometimes fail in taxiing. The Matco brakes were subsequently replaced with Clevelands. We have used the heavy duty Clevelands specified in the plans on both of our Mark lVs since 1988, and they have been more than adequate. We know of no complaints on Cleveland heavy duty brakes. Cleveland has a very good reputation, the wheels and brakes are well-made, and they are obviously simpler. We prefer the simplest solution to any problem, and subscribe to the theory, "if it ain't broke, don't fix it!". Also, the way a product performs is more important than what a spec sheet says.

MORE ON BRAKE FLUID

10/2/97

Dear Nat,

Reference Vance's column in your last newsletter about using silicone brake fluid (DOT 5). As you know, I work on Corvettes and have changed many calipers due to rust and fluid leakage, and have changed them over to DOT silicone. It is not quite as easy as Vance makes out, and can cause a few problems if not done right.

First of all, everything must be taken apart and cleaned very well to remove all of the old fluid, with isopropyl or denatured alcohol or hot water and soap, rinsed and dried. All rubber seals should be replaced if possible. Reassemble using the new fluid on all surfaces where the O-rings sit, as well as the O-rings themselves. DOT 5 is more viscous than aircraft fluid, and if shaken, will trap air bubbles. Trapped air bubbles will result in squishy brakes. If shaken, let it stand for at least 1 hour to allow the air to escape. It should be installed at the lowest point of the system to push the air out ahead of it. If air bubbles are trapped in the system, braking will not be satisfactory. Do not mix silicone fluid with any other fluid as it will result in gumming up the entire system.

Bud Meyers

CANARD INCIDENCE

If a Cozy Mark IV is built according to plans, and operated within the approved e.g. range, it should be stable in pitch (i.e. if trimmed for level flight and then disturbed, it should return to level flight) and the canard should stall at an angle of attack that prevents the main wing from stalling. Canard incidence plays an important role.

One of our Cozy builders, Nick Ugolini, purchased a Long EZ to fly while he is building his Cozy. In a conversation with him, he mentioned that in level flight, the elevator trailing edges on his Long EZ were about ½ in. down (they should have been reflexed slightly), that it climbed "like a Banshee", and when he checked the canard incidence, it was 2-1/2 deg. too low. I told him he had a dangerous airplane, and he should ground it until he corrected the canard incidence. He later wrote:

10/12/97

Dear Nat,

I have started (today) on changing the incidence of my canard based on our conversation. In my Central States Newsletters I found a procedure for doing this. When I finish the project, I will send you a full letter detailing before/after modification for the newsletter. After our talk, I did more research in the Canard Pushers and found numerous references to this issue.

THANK YOU very much for patience with me explaining this problem.

Nick Ugolini

Charleston SC

The November 1997 issue of Sport Aviation reports a Velocity deep stall accident (page 112). The builder/pilot was a licensed Airline Transport Pilot with 15,000 hours and a licensed A&E. The NTSB report said that he did not install the mandatory vortilons, he reduced the angle of incidence of the canard and he was flying with an aft c.g. The stall and resulting crash were fatal.

MARKET VALUES

We are often asked to advise both sellers and buyers as to the market value of partially built projects and completed flying airplanes. The Cozys are a very popular design. Builders selling partially complete projects usually get back all of their out-of-pocket costs, but not too much for their labor. Completed flying

Cozys (3-place), on the other hand, if they are well built and have Lycoming engines, sell in the $40,000 to $50,000 range (our 12-year old 3-place prototype was appraised at $48,500). Exceptional 3-place Cozys, like Todd Morgan's, should be worth substantially more, the sky is really the limit. On the other end of the scale, a 3-place which was poorly built and had a Ford V-6 engine, sold for under $15,000. It was purchased by the Harrises, who rebuilt it and installed a Lycoming, and was then advertised for resale at $45,000.

We only know of one Mark IV which has changed hands. It was at a reported $60,000. We think the seller could have obtained quite a bit more, and the buyer thinks he got a very good deal.

<text deleted per Nat Puffer>

EPOXY LAYUPS

Cozy builder Paul Kuntz was transferred to England, and took his project with him. He was using 2427 epoxy, and before leaving Seattle, he had a problem with poor peel strength between the two layers of glass on the inside of the fuselage sides. I advised him to strip off the second layer, sand, and then reglass, and report the results to me. He writes:

10/1/97

Dear Nat,

Before reglassing the sides, I did some tests to try to determine what went wrong. As you suggested, the time interval between layups might have caused the problem. I never had peel strength problems with the bulkheads, where the layups go more quickly, so this seemed to make sense.

So, I experimented with different lay-up techniques with samples, all using two layers of uni cloth. On each test sample, I crossed the uni layers at 60 deg. On one sample, I used pure epoxy on the foam. On another I used micro slurry on the foam. I also varied the time from the end of the first lay-up until the start of the second. I ran eight or nine separate experiments to control the variables one at a time. The lay-up with the poorest peel strength had my normal micro slurry under the first layer, a lot of squeeging and a 90 minute wait before applying the second layer. The best peel strength was where I used pure epoxy on the foam, followed by two quick uni layups. This reinforced the idea that time was the critical factor, and I needed to move faster. I resumed to my fuselage sides, and reapplied the second layer of glass. I asked another experienced builder to take a look, and he was very complimentary.

I continued using 2427, and was able to get consistently good layups with it. What worked best was to squeegee the surface well after spreading the micro, so that the slurry only filled the pores in the foam, but did not wet through the first layer of glass. Then I put a liberal coat of epoxy on the first layer of glass, squeeging but not worrying about getting rid of the excess, then putting the second layer down, letting it wet out from underneath and only having to add a small amount of epoxy where needed. This gave me a good glass-epoxy ratio, and I could not get the layers to peel apart at all. It was necessary to destroy the structure completely to get glass separated from glass, or foam, and then only by picking at strands here and there with a pair of needle nose pliers. I think I had a problem in the beginning leaving too much slurry on the foam surface, then working the slurry up into the glass layers during the subsequent squeegeeing and wetting out. This is addressed in the plans technique chapter and in the newsletters, but it seemed to take some actual practice to get the hang of it. I am confident now that 2427 can produce excellent layups when using the correct technique, and that it may have gotten a bad reputation unnecessarily. On the other hand, leaving micro slurry on the foam surface, then working it into the lay-up by too much squeegeeing of the first layer could produce poor bonds with any epoxy. I don't think humidity was a factor in my experiments.

I hope this sheds a little light on what is perhaps a stale subject, but it does show how important it is to follow the plans carefully in every aspect of the construction. Thanks for your faithful support to all of us who are building your beautiful design.

WEIGHTS

Paul sent the following weights:

F22 blkd - 2 lb 7.2 oz F28 - 10.7 oz Seat back - 5 lb 1.9 oz Lower fwd Ldg gr blkd - 1 lb 6.4 oz lower firewall - 2 lb 14.5 oz Upper fwd Ldg gr blkd - 12.6 oz center firewall - 10.2 oz Aft Ldg gear blkd - 2 lb 11.3 oz upper firewall - 3 lb 7.8 oz

Paul Kuntz

VANCE'S COLUMN

As most of you know, I have been running two electronic ignitions for some time. This arrangement along with after market fuel injection has worked out very well over the past 8 years. Yes, it's been 8 years since I installed the first electronic ignition and fuel injection. 6 months later came the second electronic ignition. I'm using Jeff Roses system. I have had one failure in 700 hours with the ignition, and that was one of the pickup transducer quit. Jeff has switched to a more rugged unit and I also carry a spare. Each system is independent except for the automatic spark advance.

A single one of these drives both units to produce the same curve. I can also advance the spark curve any time I want. This feature is not available in off the shelf units. It has been useful in that I can verify Jeff's automatic curve for optimum performance under any condition.

There are several benefits from electronic ignition. The biggest is not increased gas mileage, not smoother quieter running engine, not easier starting and lower idling rpm, but the simple fact of NO MOVING PARTS.

Along with this system are a few other items that can save you some serious money so you can spend more on other goodies. All of the following work on one or both of your stock mags, you don't have to tach to electronic ignition to take advantage of alternate wires and plugs.

If you are running REM44plugs you can switch to 37BY U and gain from 50 to 100 rpm. These are standard aircraft plugs. The reason of the gain is they stick down into the cylinder closer to the piston and have a better flame propagation. No, they don't run hotter. The 37BYUs also have less lead ball fouling.

If you want to save several hundred dollars on plugs, I suggest switching to automotive plugs. I've run them for 7 years. The history goes like this. The first ones I used were Bosch DR8BPX. They worked fine but did not have a flat mating surface and had to be turned down on a lathe. I first made them the same length of the REMs. Later I turned them so the length was almost the same as the BYUs, no rpm increase. When I made them reach longer into the cylinder a new problem surfaced. The threads were being exposed to the cylinder environment and it was tough to unscrew out of the cylinder after a few hours. Back to the original length. Once you have turned down the plug so it will accept the standard copper aircraft washer, I found 60% of the plug mating surface disappeared. This in turn deformed the copper gasket when screwing into the cylinder. Never the less, a good seal was had and worked fine. After several periods of checking the plugs I noticed that the mating surface of the cylinder head-to-spark plug was starting to dish out. This was not good. I then switched to a snowmobile 1inch plug. These monsters had the flat aircraft seat and worked well as far as the mating surfaces were concerned. They protruded into the cylinder even less, so a few more rpms were lost. The plugs were Autolite 2695, they had a 15/32" reach. I used various brands of these snowmobile or commercial plugs for several years, but the original Bosch plugs always performed better. The Bosch plugs only cost $1.75 each. The snowmobile ones cost S5.00 each and required a 1" socket to remove and replace. Last year I switched to a new Bosch plug, M8ACO. These plugs seem to perform as good as the original ones and come with the flat surface ready to go into the aircraft heads, no messing around. They were the right heat range but are not normally carried in the parts stores. You will have to order them, a minimum of 10, and they are about $4.50 each. I ordered mine through PEP BOYS. You can use any of these plugs with mags, but will have to change the end of the harness.

If you want to save more bucks, throw away your old worn out mag harness and use an automotive ignition wire. Until a few months ago I used 8.5 mm automotive racing ignition wire. This can be purchased at most any automotive store. The resistance needs to be 5000 ohms per foot. Jeff Rose told me about a new "spiral wound" automotive ignition wire. It is superior to the 8.5 mm stuff I was running. We put a set on. I figured after 8 years the old 8.5mm had enough service (although it was working fine). The new harness is a little more expensive (about $90 more per set) but look more like aircraft harness than the old ones. The new set has been on for 2 months now and works fine with no ignition noise. I have noticed no improvement over the old set such as increased rpm.

You can use the wires with your magnetos if you wish. They work fine and produce no radio noise. I have noticed about a 10 % degradation in ATIS background noise. The ATIS signal is weaker than the standard broadcast and consequently is harder to hear at longer distances. With the non-aircraft harness and or plugs, the background noise on ATIS is more noticeable. When you're closer in, the background static noise disappears. Com frequencies work just fine. I also have a FM radio tape deck installed and it picks up no noise whatsoever.

If you install a tape player or stereo of any kind I highly recommend some sort of active noise reduction system such as Bose or any other such headset. There is also an active noise canceling kit on the market that works quite well for less than $200. These units make listening to your stereo a pleasure and should not be overlooked as you will be spending many hours in your machine and spread over the life of it costs very little.

If you have any technical questions you can phone me at 817-354-8064 or e-mail me at vaatk@flash.net. Have fun flying!

Vance

AWARDS

At Vance's suggestion (he sure thinks up a lot of ideas), we had some very nice plaques made by Cozy builder/artist Lon Cooper to honor those builders who have passed the milestones of 500 hours and 1000 hours on their Cozys. These are really attractive, and truly a work of art, suitable for mounting on the headrest of your airplane, or in your trophy case, or on the wall of your office. 500 hours gets you silver, and 1000 hours gold. We would like to award these at Cozy dinners at one of the fly-ins. Let us know ahead of time if you qualify. In our own case (since we make the rules), we are going to make an exception and include our Varieze time as well as our cumulative time in 3 different Cozys, so we can display the 1000 hr award in our Cozy Mark IV.

FIRST FLIGHTS

It's a pretty important event when you make the first flight in an airplane you built yourself. We would like to have you share your experience with us and other builders. We have a note in our file that Cozy builder Messr. Bagon in France was expecting to fly this past summer, but haven't received word from him yet.

Mark Beduhn (Cozy IV 494CZ) reports:

10/15/97

Dear Nat & Shirley,

Today was the big day! I got up early (as usual), went to the airport and did a final inspection of the plane, then I filled it up with fuel. Vance Atkinson (famous Cozy pilot) graciously volunteered to fly up from Dallas and check me out prior to the first flight. He arrived earlier than I expected (took him I hr. & 38 min....wow), so he was already parked and inspecting my plane when I got back from eating breakfast. We sat down and filled out some paperwork and he showed me a comparison between the planes I'm used to flying, and the Cozy. Vance looked a little leery when I told him that I only have 120 total flying hours to my credit, but hey...you got to start somewhere. Then we discussed the plan for the day and decided that I would fly in the left seat of Vance's plane (with him in the right seat) and practice landings. After that we would decide if Vance or I would make the first flight in my plane.

Vance and I took off in his plane, climbed to about 3000' and practiced slow flight. What great slow flight characteristics! Even with the stick all the way back and the plane flying at 65 kts, the plane is fully controllable! The worst thing that would happen was the plane would start sinking...but the main wing wouldn't stall! I've heard that it was supposed to happen that way, but there is nothing like actually experiencing it. Anyway, after flying the plane at various speeds for 1/2 hour or so we entered the pattern and practiced some landings. The first thing that I noticed was Vance wanted me to fly a larger than normal pattern. That gave us more time to slow the plane down and keep things from happening too fast. He told me to fly 90 kts downwind, 80 kts base and 75 kts across the fence. I did a fair job on the first landing until short final when I let the plane get a little slow (high sink rate). WHAM!! Oops...sorry Vance. Glad the Cozy landing gear can handle some shock loading! Vance politely pointed out that I had a good flare, but next time I shouldn't do it 10' in the air and drop the plane on the runway...very embarrassing. The next landing was a little better...I only dropped it 2 feet to the runway (getting better, huh Vance). The third landing was much better (Vance said it was perfect, but I think he may have been talking in relative terms).

Vance suggested we take a break and get my plane ready to fly. He felt I could fly the plane myself (mine, not his)...First though, he wanted to do a couple of high speed taxi runs to get a feel for how my plane handles. Even though it may have sounded vain, I couldn't help but exclaim "what a cool looking plane!" when I saw him running up and down the runway in my plane. Vance taxied back, shut the engine down and said that the handling was good and he thought I should fly it. After discussing the flight plan and reviewing safety procedures...it was nearly time. First though, Regina (my wife), Mark Brandt (my friend and flight instructor), Vance and I sat down and prayed for a safe flight (Regina and I have prayed over this plane every step of the way during this project, so I didn't think we should stop now).

Then it was time. I climbed in, Vance helped me strap in, and Regina gave me a big kiss...4 times (don't worry honey... I'll be back soon). I fired up the engine, went through the checklist, then back taxied down runway 7. I did a final check and then gave it full throttle and roared down the runway. At 60 kts I rotated the nose and the plane was instantly in the air. About the only difference I noticed was the faster acceleration and climb when flying solo. Other than that, it pretty much flew like Vance's plane. I climbed to 3000' and circled the airport for about 1/2 hour. The cylinder head temps were near the red line and the oil temp was past the reline, so I was a little concerned about that. The good news though was the fact that the plane had no tendency to roll to the left or right (so I don't have to remove the wings and shim them... great!!!). Anyway...after 1/2 hour or so I entered a downwind for runway 25. The speed looked good, so I turned base and reduced the speed to 85. On final I was a little fast so I dropped my landing brake (wow, it works!), but I was still a little fast. Since I had a 5000' runway I decided to keep going and see if I could slow it down enough to land. I set the nose up slightly, closed the throttle completely, and let it settle to the runway. Still a little fast, but at least it was smooth!

I parked the plane, shut everything down, and just sat there for a minute to let it all sink in. This was the culmination of nearly 2 years (and 2300 hours) of hard work...kind of overwhelming actually. Everyone ran over and congratulated me and told me what it looked like from the ground. I needed a break, so we went out for some lunch, then came back, removed the cowl and inspected the engine. Everything looked fine so Vance suggested that we fly together to confirm that my airspeed indicator is calibrated properly. I took off after him (not quite as nervous this time) and we climbed to 8000'. It was a beautiful clear day so we could see for miles. The view of Vance catching up to me a little higher and to my right was totally awesome!!! His plane looked like it was suspended in front of a beautiful blue screen, and that I could reach out and touch him!

We confirmed that my airspeed indicator was accurate and Vance suggested that I stay up high for awhile (to keep the engine cool), but he had to get going. So he resumed to Dallas, and I circled Conway for another hour or so. The landing was uneventful! (fortunately), I parked the plane, removed the cowl and went home to tell my wife all about my second flight!!

I know that I was long winded, but figured that some of you would want to hear all of the details.

Later...I am working on flying off the 40 hours now and hope to have that done in 4-5 weeks. The controls are very responsive, and lots of fun to fly! I solved the oil temp problem. My #4 cylinder is still running 50 degrees hotter than the other ones, so I am experimenting with the baffling to get the temperature down. I will soon be taking my family places, I plan to be at both Sun 'n Fun and Oshkosh next year. Hope to see you there.

Mark Beduhn

Greenbrier AK

PUBLICITY

Larry Sligar published a picture and write-up of his newly finished Cozy Mark IV in September '97 Kitplanes magazine. Satisfied builders are the best advertising a designer can get. As promised, we will renew his newsletter subscription for another year. We haven't noticed any other Cozy completions in Sport Aviation or Kitplanes recently. If we have missed anyone, please let us know. In the meantime, we encourage you to send in your pictures and receive recognition for a job well done.

Some of our best advertising (as we said above), comes from our satisfied builders. We have been thinking of rewarding a builder who gives a ride to a friend, which results in him (or her) ordering Cozy Mark IV plans, the small sum of $50 as a token of our appreciation. What do you think? The rule would be that the person ordering plans should acknowlege who influenced him when he places his order.

HAIL STRIKES

In the middle of October we had a thunderstorm which produced hail - a very unusual occurrence here in the Valley of the Sun. The hail was driven by a 60 mph wind and the heaviest seemed to be concentrated in the area of Falcon Field where we hangar our Cozy. In front of our hangar row is a covered tie-down, where there are a lot of metal airplanes parked with their tails sticking out. Every one of them got peppered with hail, resulting in a multitude of dents on their horizontal and vertical stabilizers and fuselage. I was curious to know whether there were any composite airplanes parked outside, but could find none. Several days later I saw an appraiser with clipboard examining the damage. He said the FAA would not let any of these damaged airplanes fly until the damage was repaired, and he said the cost estimates for repairing the damaged airplanes were running from $17,000 to $30,000.

I doubt if a composite airplane would have been damaged at all, because fiberglass can absorb much more energy than aluminum, without yielding (denting). Aren't we lucky!

FOR SALE

- There has been a change in suppliers for the nose gear crank ratchet, previously

supplied by Dr. Curtis Smith. The new supplier is Bill Theeringer. His prices will be:

44807 Ratchet (plain) $49.95

44812 Ratchet (Chrome finish) 59.95Shipping and handling 5.00 Extra for Visa & Master 3.00 Contact him at:

PO Box 21645

Santa Barbara, CA 93121

Home: (805) 964-5454

Shop (805) 964-5453

Fax (805) 683-8577 - All other "FOR SALE" items remain the same as listed in Newsletter #59.

MARK IV CHANGES/CORRECTIONS

BUILDER HINTS

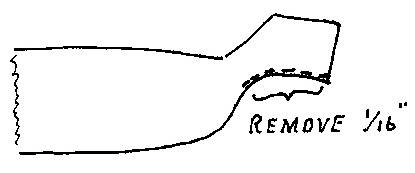

It

was suggested that we repeat a hint from newsletter 53: Some builders are still having

trouble with the trailing edge of their canards being too low, such that the airfoil dips

down and they have to mount the elevators lower than desired to get the required 15

degrees of trailing edge up travel. We suggest that you remove 1/16th inch (no

more) from underneath the fishtail on the canard templates before cutting the foam cores,

or from the foam after cutting to avoid this problem. We have made this suggestion to

Feather Lite as well to do on their pre-cut cores.

It

was suggested that we repeat a hint from newsletter 53: Some builders are still having

trouble with the trailing edge of their canards being too low, such that the airfoil dips

down and they have to mount the elevators lower than desired to get the required 15

degrees of trailing edge up travel. We suggest that you remove 1/16th inch (no

more) from underneath the fishtail on the canard templates before cutting the foam cores,

or from the foam after cutting to avoid this problem. We have made this suggestion to

Feather Lite as well to do on their pre-cut cores.- Cozy Mark IV builder Jim White asked if we could help him look for a reasonably-priced, better bearing in place of the phenolic bearing we specify in the fuselage and wing roots for the aileron torque tubes. We remembered that Dennis Oelmann sent us such a bearing to evaluate back in 1991, and we installed it in our plans model, and it has worked just fine ever since. The bearing is Nylon, with a 5/8" I.D. and is spherical on the outside. It is contained in flanged, stamped metal cage, so it provides sliding, rotating, and pivoting motion. Dennis uses them in the wing roots and on the torque tubes inside the fuselage. They are inexpensive, but can only be purchased in large quantities. Dennis and I purchased a large quantity, which I will be supplying to local builders for $1 ea. I have asked Wicks to stock them. They are identified as Triangle FMN10.

- The recommended nose wheel is the 4" cast aluminum Gerdes listed in the Wicks catalog as NWA-1230. These wheels are stronger than the Brock wheel, and the Matco wheel doesn't fit. The quantity of these wheels is limited because they were originally manufactured for the BD5. Better get your order in while the supply lasts.

LETTERS FROM BUILDERS

10/06/97

Hi Nat,

Just a quick one from England. My Cozy -COZI is now 4 years old, and has no changes or mods. I just keep filling up the fuel & oil and FLY, FLY, FLY, FLY! David Machin

9/27/97

Dear Nat,

Cozy 24 DL keeps humming along fine. June and I just resumed from Rough River where COZYs were well represented. Along with Vance Atkinson, Ken Francis, Greg Fowler, Carl Denk, and the regular crew with our COZY IIIs, we saw Chris Csida in his beautiful new Mark IV, we saw another Mark IV from Kentucky, Frank Bibbee's great Mark IV, and probably one or two more that I have forgotten for the moment.

Labor Day weekend was the five year anniversary of our COZY first flight. I have 670 hours on it now and it has carried us reliably all over the country for a lot of fun trips over those years. Thanks again for all your work and support for the COZY community. Dewey L. Davis

10/14/97

Dear Nat & Shirley,

I have well over 70 hours on my Mark IV now. We flew the 500 miles to Oshkosh in such comfort we were amazed. The Rough River Central States fly-in was also well attended. There were approximately 42 EZ's. There were a number of 3-place Cozys and several Mark IVs. My plan now is to upgrade in hardware and work on my aero cosmetics. I will be installing the electric nose wheel retract and Vance's electric pitch trim. The elevators are in perfect trim in cruise, but I need the extra range that the upgraded trim will give me. This is a wonderful airplane and I enjoy flying more than I can convey; certainly as much as building it. I can honestly say that I enjoyed building the Cozy and have since been busy building parts for other EZ's as time and my wife allow./P>

Mike Davis

10/03/97

Dear Nat

I recently tried to get some good air to air pictures of my Cozy, but that is a hard thing to do. When I have them I'll send them to Sport Aviation and get a free newsletter update, and to celebrate 1,000 hours in a COZY! That occurred 2 weeks ago on our way back home from New Mexico. I suppose that I have now flown the airplane half as much time as it took to build. I dare say that is extremely unusual for a homebuilt, at least in my experience.

There is a lot more to say about this airplane than that it has flown 1,000 hours. The airplane itself has been totally reliable, predictable and fun. With a simple autopilot it is a joy to fly on long trips with myself, my wife and the dog. I wish I had a 4place, but realistically there is all the room we need. I've flown about 50 hours real IFR in the 1,000 hours, though most of that has been climbing into sunshine at 8,000 ft. (there are lots of 800 and 3 days in Missouri). We have been to California to sail, Colorado to ski, and Maine to Wooden Boat Building School. Thanks to you Nat, this airplane has been all I expected and more.

Michael Marshall

Kansas City, MO

10/24/97

Mr. Puffer

Thank your wife for talking with me on the phone and you for providing me with a list of builders to whom I may speak with during my Great Aviation Adventure". My wife and I are both very excited about the possibility of working together to build our own airplane. During the past year I have looked at almost every design on the market and the Cozy Mark IV stands out as #1 as far as we are concerned. Most of our aviation plans are for weekend, holiday and vacation traveling which the Mark IV is perfectly suited. I will keep you abreast of our progress.

Anthony Morgan

Collinsville, VA

10/08/97

Dear Nat

I have just finished a Velocity with 3 other people. We built the thing to see if we could do it. We will be selling the Velocity within 4 years and I want to build a Cozy Mark IV. I have been researching your Cozy MK IV for quite some time and I believe it is the plane I would like to build for my wife and me. I do not plan to ever go into partners with anyone again building a plane. The cost of the Cozy compared to the Velocity is just no comparison. The Velocity is now priced out of the average home builders budget, whereas the Cozy Mark IV has remained approximately the same price for quite some time. Michael Pollock

9/10/97

Dear Nat

I am now rebuilding my sides with RAE after problems with 2427. I became discouraged and delayed the project. After helping Michael Link several times over 3-4 years on his MK IV (in primer, taxi tests to begin in 1 month) and seeing the scope of his project, I was considering other, more simple projects. My own "faith" in my choice was tested. As I kept comparing performance and capability I could not find anything that is the ballpark. If you need the speed, range & load capability, there is no better choice than the MK IV.

I received a gift certificate to Wicks from my EAA chapter which helped me back to building. This past weekend I had help on my new lay-up with a friend and his ten year old son. Although we worked over 5 hours, the ten year old was still enthusiastic about working on a part that will become a "real airplane". After knife trimming, I was having so much fun I could not quit working until I had to stop and let the next lay-up cure. I forgot how important it is to enjoy building. It feels good to be building again.

As I look ahead in the plans, I appreciate the strength of the structure and better understand your attitude '"if it ain't broke, don't fix it!" when it comes to modifications. Thanks for your efforts in putting out the newsletter. I needed to read the encouragement from others to get my "rear in gear" and start building again.

Michael Amick

Franklin, TN

10/20/97

Dear Nat

Please include a note in your newsletter that I'm interested in purchasing a completed or partially completed Mark IV. John Slater (80O) 538-5570

10/25/97

Dear Nat

After many years of stalling, and a tremendous amount of encouragement from MK IV builders on the Internet, I have decided to begin construction of My Cozy MK IV. I still live in an apartment and my most recent excuse for not starting was space. after reading Marc Zeitlin's web pages (he is building in a basement!) and talking to other builders, I decided that I can at least begin the smaller components and then move on to larger ones once I find the space. I feel great and am ready to put in my first materials order. Ed Boykin Marietta, GA

10/10/97

Dear Nat

I want to tell you about the experience I had Labor Day weekend. Jim Price (altitude record) landed his Long EZ at the Houlton airport. I met him and spent some time with him while he was here. He came to my house and looked over my Cozy MK IV and said things looked fine. That boosted my confidence! The day he left, he took me for a ride and even let me fly the Long EZ. Well, I have to tell you that it was a real privilege, as I hadn't even seen one fly, let alone gotten in one. Jim is a terrific guy and very interesting to talk to. I can't get over how well the Long EZ flies and handles. I hope mine handles as well.

Everyone up here has metal or fabric planes, and to have a composite canard airplane here was great. It really changed some people's minds about them! I just finished my floor lay-up and attached it to the fuselage. The lay-up went much better this time. Thanks for your time and patience, and the letter you sent. It really helped!

Wesley Tidd

Houlton, ME

10/10/97

Dear Nat

An update on MK0065. The fuselage, canard, center spar, wings, wingless rudders, nose, main gear, control system and trim system are done. I am glassing the inside of the turtleback and preparing to prime the fuselage bottom. I plan to mount the arm rests and prime the interior while the fuselage tub can be fumed on its side. All the interior fairings and seat backs are done. I elected to build everything rather than to use any pre-fab parts. I have been using a "rotisserie" for the fuselage and it works very well. I am amazed when I look at my progress and realize it is almost time to move the plane to the airport. Hangar space in Denver is very tight. I will have to do some searching soon.

Each 2 yr period goes by too quickly, as shown by the newsletter subscriptions and watching my daughter grow. She will be ready to fly with me by the time the Cozy is finished. Thanks again for all the time you've put into making this such a great airplane, and such a terrific building experience.

Bob Barree

Littleton, CO

10/06/97

Dear Nat

I have been following the development of the Cozy MK IV since I earned my pilot's license. I nearly ordered plans right after they were announced, but a local EAA'er talked me out of it. I followed your aft e.g. testing and the local EAA'er is wrong. Now it is almost 5 years later and I could have been done with it. I am convinced I can do it, and it will fly just fine. Thanks for all your work.

Tom Brusehaver

Bloomington, MN

10/05/97

Dear Nat,

I assume that it is interesting to you to know where your sales come from and the demographics of your customer base, so here goes: I am a 31 yr old attorney now settled in New Orleans. I have always been interested in flying but never acted upon it because of the cost and perceived impracticalities. It didn't make sense to me to get a license without being able to own a plane, and Cessna's on the used market didn't seem to make flying justifiable, given their cost and performance (lack thereof).

A few months ago I picked up the Popular Mechanics with the Zenair on the cover. I was vaguely aware that homebuilts existed but never gave it any serious thought because I assumed that such an endeavor would require a Ph.D. in aeronautical engineering. Although I didn't find the Zenair appealing, I got to surfing the net and checking out the rec.aviation.homebuilts newsgroup. Also, I need lea add that I always have to have a project - the mind-numbing practice of law isn't enough for me. I need to work with my hands (my most recent project has been to remodel my kitchen with homebuilt cherry cabinets and concrete counter tops that I cast myself).

I wanted a plane that could carry 4 people and cruise at a speed to make it truly capable of touring. Once I found Marc Zeitlin's and Brian Deford's Cozy websites, I was hooked. I also checked out the Velocity, but the ability to build from scratch with a small but steady investment over time, as well as your obvious and constant attention to safety brought me right back to the Cozy.

Joseph Hart IV

New Orleans, LA

12/1/97

Dear Nat and Shirley

Happy Holiday greetings! I didn't complete my Mark IV in September because of difficulties with painting the wings, which set me back about 8 weeks. I thought I should pass along a tip that may save others some time and frustration. I procrastinated installing the tube for the vacuum instruments from the engine compartment until the engine was mounted and I could select the best location. I recommend installing this tube when the aileron torque tubes are installed. Install the vacuum tubing parallel to but below the torque tube as it goes through the firewall 1-1/2" below MKS124 and just inboard of MKS71. Then forward through the gear box supports and above the electrical conduit to just aft of bracket CS118. From there offset down and run below the conduit through the instrument panel. This should be installed before installing the armrests. A minimum of 5/8 tubing should be used such as Aircraft Spruce #03-40800 (5/8 3003-0 versatube). They also have special fittings by Airbome (p.100). Also on p.320 is some useful information for vacuum systems regarding the regulator and air filters.

As you know, I have become a rep for Digifly GPS moving maps. For those that don't know, it has a large display screen for the GPS map, and a second page to indicate engine instruments. With the addition of a data acquiring unit, engine sensors can be monitored with alarm output. Because of limited panel space, this is a real benefit. I will offer Cozy builders a 10% discount off the "show price". Anyone wishing to obtain more info can contact me at (602) 671-7355 or e-mail at digiflysw@juno.com.

Gene Davis

Gold Canyon AZ

9/24/97

Dear Nat,

I fly a Cozy III and have designed an altitude hold feature on my Cozy to go along with the Navaid auto pilot which allows me to fly "hands off" on long trips. Do you think others might be interested? Before setting up to build a lot of kits, I would like to have several volunteers to try out some prototypes. It would cast them $200 ea. Would you please print my address and phone number in the newsletter, so I can see how much interest there is. Contact: Richard Lewis, 367 Pleasant Hill Rd., Philadelphia, TN, 37846 Phone: (423) 376-1450.

Thank you,

Rick Lewis