[Newsletters]

[Cozy MKIV Information]

COZY NEWSLETTER #64

January, 1999

Table Of Contents |

|

Newsletter Info.

Subscription Info.

Authorized Suppliers

Featherlite is now making the same propellor that Bruce Tift used to make, with Bruce’s airfoils and tooling. We previously tested and approved this prop. It is 2-bladed and very reasonably priced.

Sensenich has sent us a prop to test. We will be anxious to see how it compares to our Performance prop.

Early in ’98 I hurt my back. I don’t know whether it was lifting heavy luggage, or something else. After Sun ‘n Fun I got some steroid and pain shots which helped for awhile, but after Oshkosh I was really hurting. At the Mayo Clinic they determined that I had a herniated disk which was pinching the nerve to my right leg, so they scheduled surgery for right after Copperstate. But by the time Copperstate arrived, I was in such bad shape I could hardly walk, much less fly.

My surgery was October 14th, and the improvement has been steady since then. They say I should be completely healed by December 14th, just in time for a couple of flights before leaving for the Christmas holidays in Minnesota.

We had rented a booth at Copperstate to exhibit our airplane, but I was in no shape to fly our airplane over there, or even attend. So Gene Davis offered to show his beautiful Mark IV, just finished, and he and Carol offered to help Shirley. Mark Beduhn, on his way to the CAFÉ people out in California, flew his Mark IV in with his family, and stayed with us. Alex and Norma Strong (pitch trim fame) flew their Cozy in from California and also stayed with us.

Bryan Giesler flew over from Sun City, and there may have been other Cozys there. Everyone pitched in to help Shirley, and plans sales were brisk (better than the other times when I was there). I am told that a lot of our builders stopped by.

Attendence at the banquet was down this year. Apparently there were too many other things going on.

CHRISTMAS AND JANUARY VACATION

We will be traveling to Minnesota December 18th thru the 27th to visit our children and grandchildren over the Christmas holidays. We will try to have someone in our home/office during that time and we will try to keep current on e-mail. Then in January, from the 11th to the 25th, we hope to escape the cold weather by going farther south for 2 weeks on the beach in the sun (that is about as close to retirement as we can get). Shirley Lewis-Smith will be here to answer the phone and the regular mail insofar as she is able. We hope this won’t inconvenience you.

I recently replaced my tachometer. The original one was a very small digital with an optical pickup unit I purchased 10 years ago. It now works intermittantly and the company is no longer in business. After checking around for 2 years I decided to buy a UMA unit. They make both digital and analog, both 2" and 3" units, priced from $60 to $300. They look nice and appear to be aircraft quality. They are driven by tach generator or mag. I got the tach generator, but it interferred with the B & C offset filter so I returned it for spark plug leads. I have 2 Jeff Rose electronic ignitions and I asked UMA for two pulses per revolution. Jeff’s ignition has a tach output and produces a 12V square wave output. This drives a tach perfectly. UMA’s phone number is 1-800-842-5578 and they are listed in AC Spruce catalog with pictures. I recommend them, they are homebuilder friendly and will work with you and back their product up.

The next thing to wear out was my DigiMiniFlo fuel flow gauge. The factory said it would be cheaper to buy a new one. I bought it 13 yrs ago for $800. Now they are $1300. But there is a cheap solution. In the Central States newsletter, Charles Caldwell has designed and built a digital fuel flow meter. The price is $335.00. It comes as a kit with a flowscan transducer. If you’re all thumbs, assembled and tested is an extra $75. Charles is building a Defiant (good luck), needs two, couldn't find anything reasonable, so he built his own. Typical homebuilder. I love this industry.

I bought one. The whole thing is 1-1/4" high, 2-1/2" wide, and 3-1/2" long, just fitting in a standard 2-1/4" instrument case, but there is the rub. He doesn’t furnish a case. YOU have to come up with it. You can remote the read-out head only, which is 1" x 2" x ¼" thick.

An electrical engineer friend looked at it and said all the components were of quality. He used sockets to put the 5 micro chips in. We changed a capacitor to a bigger unit to filter out stray signals. I assembled and tested the kit in about 3 hours. If you aren’t good at soldering, I advise paying the extra bucks and be done with it. The circuit board is silk-screened with the component layout, and is fairly easy to place and attach them on it. There are 12 pages of instruction including a circuit diagram, but a few more pictures would help. You need to buy a fuse and, in case of remote mounting, some ribbon cable.

Things I wish he had done: My old unit had simultaneous readout of fuel flow and fuel remaining. This unit has one readout and you have to push buttons in sequence to get the data. He doesn’t supply dual readouts. The LED readouts are not as bright as the DigiMiniFlo, and brightness is controlled by a switch. The push buttons were a bit confusing at first, but getting better. The product is good value for the money. The unit has everything you basically need in a fuel flow system. I consider fuel flow a necessity in determining if my craft is running correctly and efficiently.

Last item. If you built my electric nose lift from the plans, be sure to secure the electric servo at the pivot end (where the ears mount into the aluminum brackets) with a stainless steel worm clamp around the outside of the aluminum brackets or drill and tap the ears on the electrical unit and install wide area washers, so the unit cannot escape. I have discovered that the ¼" thick brackets can twist under certain conditions and allow the servo mechanism to escape, folding the nose gear. Probably at an inopportune time. If you have Steve Wright’s lift, it’s already done. He uses the wide area washer method.

Have fun! Vance Atkinson COZY N43CZ 1300 hrs tt.

We monitor cozy_builders@canard.com (the Cozy builders news group on the internet) to learn the kinds of things builders are concerned with, and sometimes we provide technical information on particular subjects. We will review some of those subjects in our newsletter for those builders who don’t monitor the news group.

From the Net:

John wrote: 10/28/98

My wife of 2+ years has always been rather un-supportive of the project, but I just found out she is bragging about it to close friends. Time to smell the epoxy again.

Don replied: 10/28/98

I too have a wife who tolerated the guy who was building who knows what in the basement, until I purchased two airline tickets to spend a few days at Oshkosh. After she got nose to nose with Nat’s Cozy MK IV, and saw other aircraft that were built by doctors, lawyers, and other professional people, she began to realize that what was happening back home was magic. She has been a staunch advocate ever since. You have to do some marketing.

Paul writes: 10/29/98

The way I have kept peace in my family is two-fold. First, I spoil my wife until she feels guilty if she says anything against building the airplane. This means I give her whatever her little heart desires of my time, love, and money. Secondly, I get her involved in the project, sort of. While I am working on the airplane, she has a table and very comfortable chair at the hanger where she can do her cross stitching. In this way we get to spend time together talking while we both work on our respective projects. I won’t say this strategy will work for every couple or any besides my wife and I, just that it works for us. Every relationship is different and each couple/family must work out the balance between individual hobbies, and the rest of life.

Nat replied: 10/29/98

When I decided to build a shop, Shirley said she wanted an art studio the same size as my shop. We added 800 sq. ft. and put a folding partition across the middle so she could paint while I built.

Someone else said:

Why don’t you bring her paintings to fly-ins? She might sell more paintings than you sell plans.

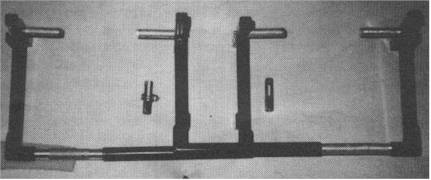

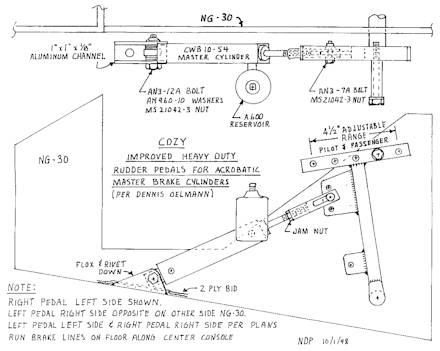

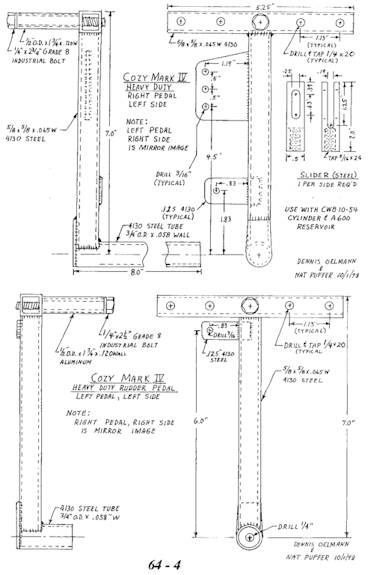

In Newsletter 24, in January 1989, we showed a drawing for rudder pedals using acrobatic brakes cylinders, which makes a nice, neat installation, but we did not provide a source for these pedals. A few builders have made their own. Dennis Oelmann, one of our favorite builders who has helped many other builders, improved upon what we showed many years ago, and built several sets for other builders. He sent us a set, and we were much impressed. He uses 5/8" x 5/8" x.065" 4130 for the uprights, so they are very rugged, they have the same adjustable feature on both sides that we only used on the right, were corrosion protected, and included all the hardware necessary for installation. They were designed to use the CWB 10-54 master brake cylinders. Dennis said he thought he could price them very competitively. He will become our authorized source for these pedals. Contact him at (319) 234-6109 or FLYCOZY@aol.com.

|

|

|

Another of our favorite builders, Jack Wilhelmson, writes:

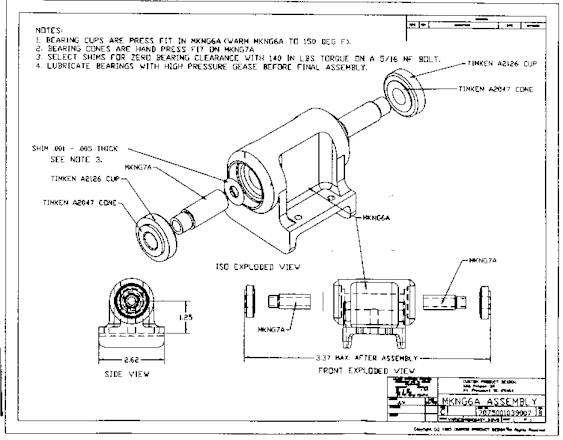

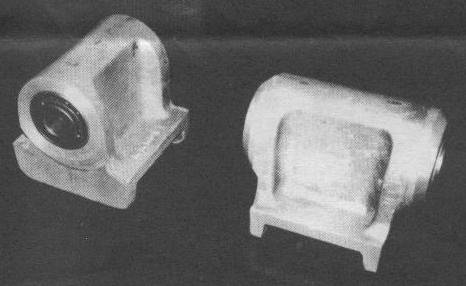

When my COZY was still in the testing phase, I was impressed with the flying and ground handling qualities, as most pilots are. Many words have been written about the flying qualities of the COZY, but not a lot about the ground handling qualities, even though they are very good. If built per plans, the airplane normally requires very light brake applications and tends to track straight on a level taxiway. As my airplane accumulated hours and landings, I began to notice a deterioration of the ground handling. It seemed to refuse to track straight and required harder and harder braking to make corrections. This led to brake heating and wear. After analyzing the problem, I discovered that excessive side to side play in the nose gear was the cause. The bronze bushings in the NG6 casting had excessive clearance. After replacing them, the ground handling returned to normal. A few months and landings later, I noticed the problem was beginning to return. I tried installing small sealed ball bearings in the casting. These failed even sooner than the bushings. It became apparent that the failure of the bushings and the bearings was caused by side impact loading during landing and side loads during taxiing. Some conservative load assumptions and an analysis of the nose gear geometry revealed that the loads could be high enough to fail the bearings. Adding to the problem was the fact that the clearance in the bearings is multiplied by about forty where the nose wheel touches the ground. The only bearings capable of repeated impact loading without failure and zero clearance preload are tapered roller bearings, that is why they are used as wheel bearings. The problem was that the smallest standard tapered roller bearing is slightly larger than the NG6 casting. A new NG6 was milled from a solid block of aluminum and the tapered bearings installed. This has been in my airplane for four years and many hard landings with no increase in nose gear side play or deterioration in ground handling. In the last four years I have made five of these for other people with Long Ezs and COZYs. After trying to get Ken Brock to make and market them (Ken can’t change a Burt Rutan design), I finally made a casting pattern that works for the Longs, Cozys, and MKIVs, and I had a short run of them cast. The aluminum is an aircraft grade and the castings have been heat treated to normalize them for machining. The bearing races are press fit in the casting. The bearing inner races are light press fit in two spindles that have a .322 dia. hole and accept the original 5/16" dia. mounting bolt. The preload on the bearings is controlled by the length of the two spindles. The original mounting holes are left out of the casting, so that if the unit is being retrofit to an existing airplane, the bolt holes can be match drilled to fit the nose gear parts. The installation is best done by putting the gear in place before the flox between the casting and the gear strut cures, and checking for equal clearance on both side of the strut in the retracted position. On new construction, the installation is the same as the old casting, except that the mounting holes must be drilled. I can drill these holes at no added cost if you ask. Contact me at (843) 884-5061 or Wilhelmson@scra.org.

|

|

The main landing gear strut for the Mark IV is a proprietary design of Co-Z Development. It was designed to be very strong (half way between the Long EZ and Defiant). It should not spread and take a permanent set over time. Camber was designed into the strut so that it would be negative (wheels tilted bottoms in) when the aircraft is empty, and close to zero when the aircraft is loaded to gross, and not too far positive when the gear spreads in a hard landing. It is a spring and should return when the aircraft is empty. Featherlite is the only supplier that has our permission to use our design, it is the only supplier highly recommended by Burt Rutan, their gear is the only gear we have tested, they are the only ones we have authorized to reproduce it, and their gear is guaranteed 100%. Recently a new builder asked the Internet group whether there was any difference between the struts made by Featherlite (FL) and unauthorized copies (UC) made by someone else. One builder, not yet flying, said he didn’t think so (he had purchased a UC strut). A builder/flier David Domeier, said that after 5 months of flying he thought his gear had spread, because the wheel camber seemed to have changed. He said he had an UC strut, and asked if anyone else had the same experience.

We have the two oldest Mark IVs and were not aware of any gear spread in our prototype Mark IV, now 10 years old, nor have we noticed any in our plans model Mark IV, over 6 years old, both of which have Featherlite Mark IV struts, so we decided to make a quick survey. Most builders already flying do not participate in the internet group, so we did some telephoning. We called up 5 builder/fliers who had been flying around 2 years. We didn’t find anyone with a Featherlite strut who thought his gear had spread, but we did locate two more builder/flyers with UC struts who thought their gear had spread and that they had lost wheel camber.

To avoid relying on opinion, it seemed prudent to get some actual data. There is a simple test to determine gear spread. If the gear spreads, wheel camber changes. So all you have to do is to measure camber when the airplane is new and empty, and each 100 hours or annual thereafter (at the same weight), and record it in your aircraft log book. Camber is easy to measure. Do not "set" the gear. Make sure the floor is level, or level it. Then set a carpenter square against the wheel. A 5" Cleveland has a flat area on the rim which is 6" wide. Measure the distance from the square to the rim at the bottom of the wheel and at the top. Do this after pushing the airplane forward at least 5ft., and then after pushing it aft at least 5ft., and take the average, to eliminate the affect of toe-in. The wheel should be tilted bottom inboard (negative camber) when empty. A ¼" difference between bottom and top of the wheel calculates to 2.5 degrees, and 5/16" is 3.0 degrees. Record this in your aircraft log book. Our plans model, after almost 500 hours logged and several hundred landings (some pretty hard) has an average camber of 2.7 degrees negative (bottom tilted inboard) when empty, which we think is about what it was 6 years ago (We hardly ever "set" the gear). We assume that the UC strut is a copy of our proprietary design, but we don’t know if it is made the same way as Featherlite. We asked David Domeier and the two other builder/fliers with UC struts who thought they had spread to make the same measurement of wheel camber. Here are the results reported back to us:

| Builder | Strut | Time Flying | Camber |

|---|---|---|---|

| Co-Z | FL | 6 years | -2.7 deg.(bottom in) |

| DD | UC | 5 mos | +0.2 deg.(bottom out) |

| FB | UC | 2 years | +1.9 deg.(bottom out) |

| TM | UC | 2 years | +2.0 deg.(bottom out) |

We don’t know what the camber was on any of these aircraft when they were first completed, but if the struts were the same shape as ours, one would expect the wheel camber would have been the same as ours initially. If so, this data suggests that UC struts spread over time, and have taken a permanent set, as suspected (We don’t know how much a strut would have to spread to change wheel camber by 4.5 degrees, but probably quite a bit.).

A main landing gear would be very difficult to replace. Featherlite has a very good track record for over 18 years making struts for the Varieze, Long EZ, Defiant, Grisley, other Rutan designs, and Cozys, so we have no reservations about their quality. We urge our builders to use only the Featherlite strut. We are asking Featherlite to keep Mark IV struts on the shelf so builders will not have any reason to buy from anyone else.

The flight test evaluation of the Mark IV by Ed Kolano, published in Nov. ’98 Sport Aviation, was the result of Cozy builder Joe Lane’s efforts. Ed Kolano is a very highly respected test pilot and has been evaluating various airplanes for Sport Aviation, including several different canard airplanes. Joe Lane wrote to Jack Cox and said that some of the unfavorable reports about other canard airplanes caused some builders to wonder if the same was true of the Cozy Mark IV (pretty slick, huh?). If you can get through all the technical stuff, his evaluation was very favorable. Among other things, he determined that the Mark IV does not exhibit adverse yaw when one applies only ailerons. That is, the nose doesn’t try to go right when you apply only left aileron with no rudder. He thought the pitch trim was quite sensitive, but that is characteristic of Alex’s pitch trim. The mechanical pitch trim is less sensitive.

Mark Beduhn flew out to California so the Café foundation could evaluate his Cozy Mark IV. It may be a few months before it is reported in Sport Aviation, but we were pleased when Mark told us that he was told that his Mark IV performs closer to the designer’s specifications, than any of the other designs they have evaluated to date. If this is true, we are very pleased.

- We were pleased to learn that Uli Wolter is flying again. If you recall, when he was a NATO instructor in Texas, he was the first builder to complete a 3-place Cozy. He then flew it from Texas to Germany. He became our international representative. On one of his fly-in trips to Stockholm, Sweden in June 91, he had an engine-out, caused by loss of oil, and couldn’t make it back to the field. His emergency landing caused quite a lot of damage. When he started making repairs, he decided to convert his Cozy into a Cosy Classic (the German version). This was quite a large undertaking (he saved only the wings),but he finally finished. His airplane is really loaded with all kinds of goodies (empty weight 1235 lbs.). His maiden flight was on Sept. 21, 1998 in Augsburg. It was a rather short flight due to high CHTs on #3 & #4, caused by too large an air filter, but that has been corrected. He say his Cosy Classic behaves very similar to his old Cozy N-52CZ and it’s hard for him to believe that it was over 7 years since he last flew a pusher. Congratulations, Uli!

- Tom Waters writes:

9/28/98

Nat,

Lift off of N26TW was at 6PM Sept. 3rd. Trim was heavy to the right. I have about 8 hours now. I did everything wrong but the plane came through just fine. Still trying to cool the oil down some (it’s at 210 deg.) and working on the oil lost through the breather. No return inlet place for oil from the separator on the 0-290. Trying to get more cool air on the oil cooler also, otherwise just slowing down my landing speeds and increasing my forward c.g. range a few pounds at a time. Regards,

Tom Waters

Clopton,AL

Since our last newsletter, we have sent checks for $100 or a Strong pitch trim kit to the following for the favorable publicity they have received on their Cozys:

Bruce Elkind (Oct. Sport Aviation)

Kevin Funk (referral)

Gene Davis (manned our booth at Copperstate)

Tony Rothman (publicity in Australia)

Bob Misterka (Nov. Sport Aviation)

$$$$$$$$ 4 U - $100 OR STRONG PITCH TRIM

EAA members, and readers of Kitplanes magazine love to read about what other builders are building and flying. We have a lot of builders who are flying, but never sent in pictures to any of the magazines. Maybe they didn’t think it was worth the effort. So we decided to increase the ante. When we mentioned this to Alex Strong, he suggested we offer builders a free "Strong" electric pitch trim, or, if they have already purchased one, $100.00, for any pictures and descriptions or articles published in Sport Aviation or Kitplanes Magazines.

Let us know when you submit (so we can watch for it to be published) and let us know what you wish to receive. Submit your pictures and write up to:

We are so used to fueling our own cars that some people don’t realize that more precautions might be necessary in fueling an airplane, particularly a "plastic" one. Cars, of course are all-metal, with metal tanks, and the opening into the tank is about the same size as the nozzle, so "grounding" or "bonding" occurs automatically.

If you remember in high school physics, the Van De Graaf generator can charge up an insulated object to a high enough potential to generate a huge spark. A stream of fuel pouring into a non-conductive tank has the same capability. A charge will build up on the surface of the fuel until it reaches a potential great enough to generate a spark back to the nozzle. If the fuel-air mixture is flamable, a flash fire will occur. The grounding wire normally connected to the exhaust pipe, or the step accomplishes nothing.

The only safe way to fuel your airplane is to attach a braided grounding cable 18" to 24" long to the fuel cap, extending down into the tank, and then connect a grounding wire (24" long with alligator clamps at both ends) from the fuel nozzle to the fuel cap, before inserting the nozzle into the filler neck. If you don’t do this, someday you will have a fueling fire which could destroy your airplane.

We hope everyone keeps a fire extinguisher in his airplane in a location where it is easy to grab if you have a fueling fire or a brake fire. We keep our extinguisher in front of the shoulder support on the pilot (left) side.

It would be very difficult to define the requirements for roll over protection that would be adequate in every conceiveable situation, unless you installed a landing gear on top of the airplane similar to the one on the bottom. The Mark IV offers much protection because it has only a half-bubble canopy, with the aft half being fiberglass. Also, in addition to the headrests and fiberglass turtleback, the Cozy has a very substantial bulkhead immediately behind the pilot and passenger. The only time this structure has been put to the test that we are aware of, is when the Harrises rebuilt Merle Musson’s 3-place Cozy and were flying off the time. Mr. Harris had an engine failure, and put the Cozy down in a very muddy farm field. He made ruts about 8 in. deep before the Cozy flipped over upside down. It was pretty much totalled, with wings and canard ripped off, but the canopy was unbroken and Mr. Harris was not injured. Hope this gives you reassurance.

A Cosy Classic builder/flier, Carl Denk, reported a failure of his MKNG15A nosewheel casting after approx. 670 hours flying. He volunteered that he flies well over gross at the maximum forward c.g.(maximum load on the nose gear). This was a big surprise to us, because this part was designed to be substantially stronger than the equivalent part on the Long EZ, and there are a large number in service without any previously reported problems; so we asked Jack Wilhelmson to make an independent design study. Jack assumed the worst case, 2050 lbs gross, max. forward c.g. @ 97.5, and a 2g landing (that’s a pretty hard landing!). Neglecting the flox bond and also bolt tension, the safety factor was 2.1 (1.5 is required). The flox bond increases the safety factor, but the bolt tension reduces it! In other words, load carrying ability is inversely proportional to bolt tension. He found that one could actually break the ears off the casting before the bolts would break. Jack concluded that to maximize the safety factor on service load carrying ability, the bolt tension should be held to an absolute minimum, say no more than 10 inch-lbs. We will add this warning in Design Corrections/clarifications.

Page 35, Main landing gear: Check wheel camber. When aircraft is empty, wheel camber should be between 2.5 to 3.0 degrees negative (bottom of wheel tilted in). Measure after pushing aircraft forward at least 5’, then aft 5’ and take average. Record in aircraft log book.

When checking for proper toe-in, wheel camber should increase slightly when pushing forward and decrease slightly when pushing aft.

Page 50, Annual inspection: Check wheel camber and toe in as prescribed on page 35 and record in aircraft log book.

Mark IV builder Mark Loy says he used double-sided tape on the forms to hold the fuselage foam down and it worked pretty darn good. He used the type used on golf clug grips (You might also try carpet tape). He said the tape peels right off the foam with little or no effect on the foam and it held fine during the layup. He says his layup came up quite well with no defects.

Marc Zeitlin says you can see MkIV Changes/Corrections by calling up cozy.canard.com, then "Newsletters", then "Table of Contents" & then "MKIV changes/corrections".

Strakes, Chapter 21, p.2. Please note that the fuel cell ends at Rib R-57. The empty space outboard is necessary as a buffer to prevent any fuel, liquid or vapors, from reaching the wing. An open drain at the low point would indicate any fuel leakage through R-57.

Super heavy duty Clevelands have 3/8" thick discs.

IO-360 200hp. Zero since major. New factory cylinders. Rebuilt to factory new limits. $12,500 plus crating and freight from Dallas TX. P16pen@gte.net

Rebuilt aircraft instruments, much less expensive than new, guaranteed. Contact: Howard Francis, 5613 S. Crows Nest Rd., Tempe, AZ 85283 (602) 820-0405.

Cozy builder, Bill Walsh, makes tee shirts and sweatshirts in various colors and adult sizes. They have a picture of the Cozy Mark IV on the front and back He may have other items, such as jackets, caps, and pins. Contact him at PO Box 160884, Altamonte Springs FL 32716. Tel(407) 695-3543.

Cozy builder Wayne Lanza supplies an electric speed brake actuator kit with all the parts needed for installation, with instructions for $275. He now has a switching and breaker panel for the Mark IV. It is similar, but not identical to the one we had made for our plans model. He is using the highest quality DC switches and circuit breakers, and pre-wires the panels, making the rest of the electrical system installation very EZ. Cost is $425. We heartily recommend his products. Contact him at: 9425 Honeysuckle Dr., Sebastian, FL 32976 (561) 664-9239.

Vance Atkinson supplies fuel sight gauges. They are a clear bubble with a white background. $35 per set. Contact him at 3604 Willomet Ct., Bedford, TX 76021-2431 (817) 354-8064.

Steve Wright is making electric nose-lifts for the Cozy 3 and 4 aircraft. It will raise the nose with full fuel and baggage and at least one person sitting in the front seat. We have installed one and like it. Contact him on (615) 373-8764. See "Letters".

Alex Strong is making a neat electric pitch trim system. Cost is $175. We have installed one and like it. Contact him at (760) 254-3692.

Featherlite (see "Authorized Suppliers") makes many pre-fab parts for the Cozy 3 and 4, including pre-cut wing and canard cores. We have used all of their parts and can vouch for the quality. They have also taken over the manufacture of baggage pods and propellors from Bruce Tift’s estate. These were good propellors, with a urethane leading edge, and we are pleased to see that they are available again.

Dave Dent writes on 8/3/98: I was with Catto over the weekend and he says that he is back into building props. He was out of the prop business for awhile because of another business venture. The going rate for a three bladed composite runs right around $1600. Not bad for something that keeps your plane in the air.

I have been running a three bladed composite now for almost six years, and you would have to fight me to get me to change. I have a Long EZ with 1300+ hours on it and all but around 400 hours has been with this prop. I climb out at 1800 fpm and can cruise better than 205 mph. It is very smooth and quieter than the two blade props. You can reach Catto at (209) 754-3553.

PosiTech International manufactures and distributes new oil coolers for experimental aircraft, home builts and kit planes. They have a line similar to the Harrison that we use. They are priced competively and backed with a 2 year warrantee. They can be reached at (800) 367-1374.

Ken Grakauskas, 1801 Airway Dr, Sanford MI 48657

Craig Pomaville, (810) 677-4811.

Cozy Mark IV beautifully built, 70 TT. Flies like a dream. 0-360 Lycoming, Ellison throttle body, electronic ignition and 3-blade Performance prop. ICS plus nav/com, Apollo 618 Loran, Navaid auto pilot, Terra encoding transponder/mode C, Rocky Mtn engine monitor and intercom. Well proven and tested. 200 mph cruise. $89,500. We are building a new home. Contact Larry Sligar (541)863-3222.

6/10/98

Nat,

We have shipped over 80 noze-lifts all over the world, and demand is still strong. Overall feed-back from customers has been good. If anyone has any problems, I encourage them to let me know. We are always looking for ways to improve the system. We have done some redesign to reduce the parts count, to increase the strength by a small margin, and to try to keep the price the same.

Vance Atkinson has agreed to test our modifications and is flying with the redesign. We await Vance’s comments.

We have mailed out our second newsletter, which contains an inspection procedure. We recommend inspection every 24 months or 150 hours.

Steve Wright

1400 Robert E Lee Ln

Brentwood, TN 37027

11/5/98

Dear Nat & Shirley,

It’s been a year. My Mark IV looks like a boat with a wing. Hopefully in another year it’ll look like an airplane.

Thanks for the great instructions. It is something I enjoy spending time building and working on the plane. I learn something all the time.

Tom Brusehaver

Bloomington, MN

10/1/98

Nat,

Things are going pretty well, the fiberglass work will be done in another month or two. The control system is almost complete. A beautiful 0-360, completely rebuilt with new crank and cylinders etc., is on the floor, ready to bolt on. Hope to fly next year. Thanks for your continued support.

John Epplin,

Orion, IL

9/28/98

Dear Nat,

I am still working on Cozy III #466. Progress has been slow due to health problems. Enclosed is a picture of my rudder pedal and brake cylinder installation. I am using the Cozy IV Brock nose gear which fits and functions properly. My canard and elevators are complete and fitted to the fuselage. I am nearing the end of chapter 13.

L.G. Smalley

Geneva, IL

10/15/98

Dear Nat and Shirley,

I recently sent pictures of my 3-place Cozy N342RM to Sport Aviation and Kitplanes.

I originally had high CHT on #3 cylinder during climb out. I added some baffles to the bottom of the cowl and alleviated that problem. I still need to do some additional work to even up the CHTs. I had copied Vance’s oil cooler arrangement using a NACA scoop aft of the right side of the canopy. I wasn’t getting adequate air flow and had high oil temps. I replaced the 8 row Harrison cooler that came with my high time 0-320 with a new 9 row Stewart Warner 10599 cooler. I also changed the location to the recommended position in the left side of the bottom cowling. My oil temps now run 180-190 degrees. I also replaced my remote oil filter with a B&C angled oil filter adapter. I added a smart coupler to connect my Airmap handheld GPS to the Navaid Devices autopilot. It works very well. I also added taped music input to my intercom. Next year I plan to get serious about aerodynamic cleanup and propellor performance optimization.

The more I fly this airplane the more I like it. It is truly a fine design. Thanks again.

Bob Misterka,

Grafton, MA

10/16/98

Dear Nat,

Just wanted to say hello and wish you a speedy recovery from your recent surgery. I also wanted to share my recent success with finishing Chap. 10 (canard). After finishing the top spar cap and skin, I trimmed the canard ends equidistance from center. I used my engineer scale as makeshift balance on my table and turned the canard over and tried to balance it with the centerline on the engineer’s scale. It resembled a teeter totter. Well, it tipped to one side and I thought to myself, you can’t win’em all. Sooooo, how out of balance was it? Well, it only took 1 wooden mixing stick (.3 oz.) placed 18 inches from the light end to balance the canard. I thought, Damn, I’m good!!

I’ve also set the elevator hinges and they work great. Don’t know if this is a builder tip or not, but when trying to insert the hinge pins through NC-3 hinges, I placed a dab of vaseline on each side of the hinge hole to hold the 960-10L washer in surface tension on the hinge. I then could hold the hinge and washers with one hand and insert the pin with the other. It worked great!

I mentioned the last time we talked on the phone that I had bought a small LASER LEVEL. It’s a small unit about the size of a tri-fold wallet that projects a thin red laser beam accurate to 0.05 inches at 33 feet. It helped me get the leading and trailing edges of the elevators and canard dead solid straight. I wish I had bought it earlier as it would have made setting the landing gear toe-in very easy and highly accurate. It only cost me $105 at an engineering tool supply center. It also has an adapter to clamp it to a regular spirit level. It is threaded and can be attached to a tripod. This will make aligning the wings very easy and very accurate. It can be tilted in 2 degree increments up or down to set off-level angles. To me the price is worth the accuracy and improvement in workmanship it allows. Take care and I hope you are up and about real soon.

Kevin Short

Lexington, SC

10/13/98

Dear Nat,

Hear via the Cozy Web that you are having difficulty with a leg. Growing old isn’t great, but sure beats the alternative. Judy and I have more than once asked what happened to our 25 yr old bodies. Just a note to wish you well, and praying for a speedy recovery. Personnally, I believe you add a great deal to the continuation of the Cozy success, and selfishly don’t even want to think about something which would pull you away from it.

Marv Bishop

Hermosa, SD

10/1/98

Dear Nat & Shirley,

Mark IV #623 is coming along much better now as I am able to put more time into it and am beginning to understand the whole picture a little better. We put the bottom of the fuselage on this last weekend with the help of my brother-in-law who is visiting from Israel. I used the new epoxy L335 on the bottom and am very happy with it. It seems to me to be stronger and the long pot life was very helpful. With our lovely heat, the RAE was just curing too fast.

The more I accomplish, the more fun it becomes so I have to be careful to still spend plenty of time with Sarah and the kids. Thanks for all the fun!

Jeb & Sarah Butler

Chandler, AZ

10/12/98

Dear Nat,

Please renew my newsletter. I thoroughly enjoy reading each one the day it arrives. Thank you for all the hard work that goes into making such an informative newsletter.

Marvin Royster

Stone Mountain GA

10/17/98

Dear Nat,

Time to renew my newsletter. After all these years I still look forward to that document. Terrific job, Nat, and keep up the good work. You seem to be working harder than when you worked at 3M. Is that an accurate statement? Thank you.

Roger Roy

Abington, MA

10/19/98

Cozy builders,

I just returned from Santa Rosa California where the CAFÉ foundation conducted a series of flight tests of my Cozy MK IV. They are still analyzing the data, so I don’t have the results yet, but they will be published in Sport Aviation in a couple of months. Overall the experience was fantastic! I met some very dedicated, talented and professional aviation enthusiasts who were a pleasure to work with. I feel very fortunate to have had the opportunity to get my plane analyzed in such detail.

C.J. Stephens (the test pilot) did share some comments with me. Overall he liked the plane and said that it performed very closely to the numbers published in the Owner’s Manual. He said that matching the numbers in the manual is very unusual, and is a real credit to the designer (Nat Puffer). He (the test pilot) built and owned a Verieze, and he said plane flew very much like his except mine has more power and is harder to slow down for landing (probably due to its increased mass).

Again, it was a great experience and we are fortunate to have an organization (the EAA) that has the vision to sponsor the CAFÉ Foundation. PS: We (my wife, two girls, and I) stayed at Nat and Shirley Puffer’s house for a couple of days on the way to Santa Rosa, and their hospitality was second to none (even though Nat was laid up).

Mark Beduhn

Greenbriar, AR

11/17/98

Dear Nat,

I am really very much surprised with the high quality of the Cozy Mark IV plans. Really, like you said in your web site, a step-by-step information provided plans. Reading the first time looks not very difficult to build the Cozy (but I am sure some (lots of) difficulties are coming soon. I think, after seeing the plans in my hands, I did a great acquisition

In spite of some of the comments in the Cozy mailing list, I have my own opinion about things, to be sure, and you make me a believer in your points of view. So let’s go ahead, Nat.

And, one more time, thank you very much, you did a fine job. I am really very, very satisfied with what I have in my hands right now.

Romulo Augusto Lt, MD

Belo Horizonte

MG Brasil

If you’re ever faced with a forced landing at night, turn on the landing lights to see the landing area. If you don’t like what you see, turn ‘em off.

The only time you have too much fuel is when you’re on fire.

Hovering is for pilots who love to fly, but have no place to go.